chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,192

I put together a couple of 25 ah 24 Volt 8S Packs and made my own busbars for this.

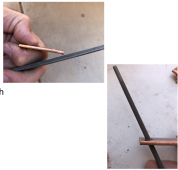

I chose 1/8" X 3/4" 110 Copper bus bars. •https://www.ebay.com/itm/303841271273 These are rated for a little over 200 amps. Way more than these 25 ah cells will push. I'm deciding to learn how to make my own busbars at $1 per inch.

I ended up getting two copper flats, 12" each. Each 12" section made 6 busbars for my cells, so 12 total. I only need 7 for each battery. THis is the E-Bay pic. Slightly cleaner than the ones that showed up in the next pic.

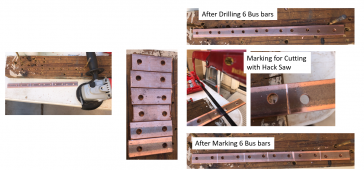

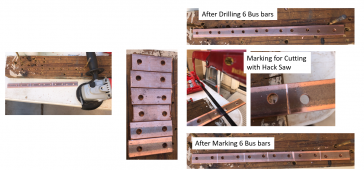

Of course I am not tooled up for this, so here is my drill press, simply a 2 X 4 with two drill bits to hold the bar steady as I drill:

I had a pattern I used to mark where to drill holes and then used a screwdriver to make an indentation to drill on:

I found that if I drilled the M6 hole with the perfect size first, 15/64" the bit would wander. This is why I wish I had access to a real press. First was a smaller 3/32" Hole and then with a 15/64" hole, and then after each pair of holes was drilled, saw if they fit on the batteries. Some were drilled too far apart, again whish I had a drill press:

Then was marking and cutting. You can see the holes are not perfectly centered. I marked with a hacksaw where this was going to be cut. Final Cutting done with a power tool. Also note the oxidation on the copper that needs to be cleaned off:

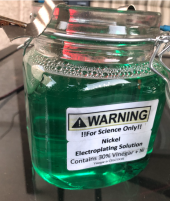

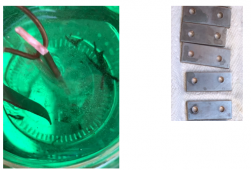

Had to clean the bus bars off prior to nickel plating. Used

•Rubbing Alcohol

•Acetone Better

•Paper Towels

•800 Grit Paper on sanding block

•Various Files

•180 Grit Sanding block (Not Pictured)

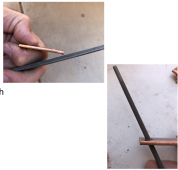

First came the filing:

Then sanding with 180 grit block which got rid of the last of the burs from the drilling and then finishing with 800 grit. Much Shinier, but still needed cleaning with alcohol or acetone:

I chose 1/8" X 3/4" 110 Copper bus bars. •https://www.ebay.com/itm/303841271273 These are rated for a little over 200 amps. Way more than these 25 ah cells will push. I'm deciding to learn how to make my own busbars at $1 per inch.

I ended up getting two copper flats, 12" each. Each 12" section made 6 busbars for my cells, so 12 total. I only need 7 for each battery. THis is the E-Bay pic. Slightly cleaner than the ones that showed up in the next pic.

Of course I am not tooled up for this, so here is my drill press, simply a 2 X 4 with two drill bits to hold the bar steady as I drill:

I had a pattern I used to mark where to drill holes and then used a screwdriver to make an indentation to drill on:

I found that if I drilled the M6 hole with the perfect size first, 15/64" the bit would wander. This is why I wish I had access to a real press. First was a smaller 3/32" Hole and then with a 15/64" hole, and then after each pair of holes was drilled, saw if they fit on the batteries. Some were drilled too far apart, again whish I had a drill press:

Then was marking and cutting. You can see the holes are not perfectly centered. I marked with a hacksaw where this was going to be cut. Final Cutting done with a power tool. Also note the oxidation on the copper that needs to be cleaned off:

Had to clean the bus bars off prior to nickel plating. Used

•Rubbing Alcohol

•Acetone Better

•Paper Towels

•800 Grit Paper on sanding block

•Various Files

•180 Grit Sanding block (Not Pictured)

First came the filing:

Then sanding with 180 grit block which got rid of the last of the burs from the drilling and then finishing with 800 grit. Much Shinier, but still needed cleaning with alcohol or acetone: