Okay. You can stop fighting. I understand no panel gives the rated output. The panel will be on a van. I will only have room for one panel. So I'm looking for the highest watts I can get on a 12 volt system.

Physical space constraints are your biggest limitation. You might find you can "tetris" several smaller panels on the roof and get more total power.

To insure you harvest maximum available power, divide panel power by 14 to determine how many amps the charge controller needs.

Flat panels perform particularly terrible in Winter. It's not uncommon for a flat panel to harvest only 40% in winter when compared to summer performance. You can offset this by designing a mounting system that can tilt, and/or carrying additional small flexible panels that you can quickly deploy - even hanging them on the side of the van can significantly improve harvest.

Lastly, a DC-DC charger is always desirable to insure you always have a means to charge.

Using a charge controller to lower the voltage seems like there should be a loss to me. But I guess not. Thanks for the help.

There is, but it's typically very small, 2-3%. MPPT is a sophisticated DC-DC converter that can find the optimum PV voltage and current to deliver maximum power.

The prior "state of the art" in charge controllers was PWM. PWM works by shorting the panel to the battery, so you have to use panels of suitable voltage, typically 17-18V, and their performance is compromised because they're not permitted to operate at their optimal voltage.

MPPT can permit harvest of near 100% of the available power the panel can produce, where PWM permits only about 80% of available panel power.

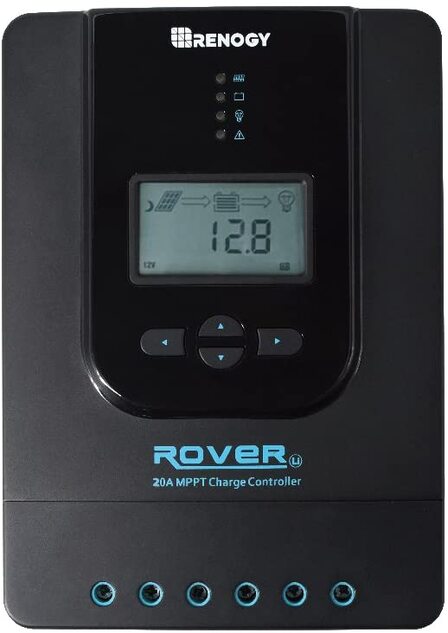

Speaking of MPPT vs. PWM, there are a number of bogus "MPPT" controllers that are actually PWM. If you find a cheap MPPT, you've probably found a bogus one.

Will lists several reasonably reputable MPPT SCC on his site:

Building a vehicle mounted solar power system? Let me help.

www.mobile-solarpower.com