So I stumbled upon this gem. This Sun Fun Kits guy uses electronic load in constant power mode (!) without V-sense leads (!!) and tried to compare LFP cells. I tried arguing for using Vsense and constant current mode but this guy is adamant. No wonder why battery manufacturers do not deal with small companies or end users. Too much clueless jokers like these:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sun Fun Kits guy has no clue

- Thread starter AntronX

- Start date

sunshine_eggo

Happy Breffast!

I agree there are better tests and methods, but he's using it consistently on a comparative basis. I see no issue with using this as a screening test, and I concur that he is weeding out lower quality cells.

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

The "Character" who is SFkits got tossed from here and other places.

The guy even managed to get a REP with several vendors and up...

The guy even managed to get a REP with several vendors and up...

He is loading already weak cell to 200A while good cell to 80A. There will be no consistency because every cell will be tested at different load current. Constant power mode is wrong mode for this method. Got to use constant current...but he's using it consistently on a comparative basis.

sunshine_eggo

Happy Breffast!

He is loading already weak cell to 200A while good cell to 80A. There will be no consistency because every cell will be tested at different load current. Constant power mode is wrong mode for this method. Got to use constant current.

Did you watch the second test of the "bad" cell?

Cell 1 ("good"): 82A, 3.0V

Cell 2 ("bad"), second test: 50A, 2.5V

With a substantially lower current, there is substantially more voltage drop.

The biggest issue I see is that he is assuming that all of these cells are at the same SoC, and I've personally seen "as received" variations of 30-50%.

IMHO, the biggest risk I see is that he may toss decent cells out as bad when they are simply at a lower state of charge than the "pass" group.

Again, I don't disagree with you that there are better tests and methods, and I'll also state that the "boastful" statements made during the course of the video are all about self-promotion.

I would have greater confidence in cells that "pass" this test than completely untested cells; however, a simple IR measurement with a $50 YR-1035 will probably yield similar results, and it would do so independent of SoC.

I did not at first. I saw it up to 200A part. That cell is weak but all that boasting and incorrect testing method is LOL. And his insistence that he is testing the power a cell can provide is a fail.Did you watch the second test of the "bad" cell?

sunshine_eggo

Happy Breffast!

I did not at first. I saw it up to 200A part. That cell is weak but all that boasting and incorrect testing method is LOL.

Yeah, the boasting was quite off-putting and almost had me to your level of outrage... until I saw the second test that clearly indicates a lower performance level for the "bad" cell.

I have several tools at < $100 that would yield better results than his test, but if he wants to screen them that way and possibly toss good cells, then more power to him.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

Worst thing about the video is where he says 'this is something we would sell', Both cells tested are garbage in my opinion.

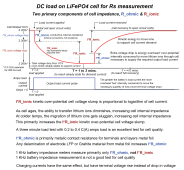

The Ugly:

#2 gauge welding cable 3.5 to 4 foot long pair with 150 amp Anderson Connector

No remote sensing cell voltage so cable loss drops displayed in voltage readout.

4 feet (x2) #2 welding cable about 1.4 milliohms. Anderson connector approx. 0.1 milliohms, instrument lugs about 0.2 milliohms

Total cable + connectors resistance about 1.7 milliohms.

1:25 mins timestamp

First battery test OCV = 3.283v, about 40% SOC. Used cell.

1:40 mins timestamp

Turned on 250 watt load.

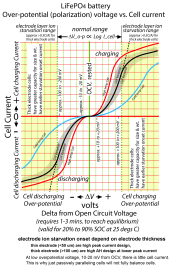

Instrument immediately drops to 2.735v @ 91.413amps (250.00 watts, 0.33 CA discharge

Adjusted for 0.155v cable loss, cell at 2.890v @ 91.413amps (0.33 CA) ), 264.2 watts from battery

Battery initial Rs = 3.283v - 2.890v = 0.393v, /91.413A = 4.3 milliohms initial Rs drop. Very bad. Should be like 0.40 milliohms. About 10x worse than newer cell. Compare to first video with SFK260HP battery.

0.393v * 91.413A = 35.93 watts loss for 264.2 watts delivered, 86.4% efficiency. This is very poor.

2:21 mins timestamp

44 secs of load, not at equilibrium yet.

Instrument 3.028v @ 82.571 amps after 35 second with load. He says warming up, really? Ion diffusion is so bad at room temp it needs to get above room temp to get more ion flow. Imagine how this cell would perform at cooler temps. Your inverter may shut off for low batt voltage preventing battery warmup current from occurring.

Adjusted for 0.140v cable loss, cell at 3.168v @ 82.571 amps (0.30 CA), 261.6 watts from battery.

3.283v-3.168v = 0.115v, /82.571A = 1.39 milliohm Rs. Improved due to cell internal heating but still very poor cell.

0.115v * 82.571A = 9.5 watts loss for 261.6 watts delivered, 96.4% efficient @ 0.295 CA discharge rate. A good cell should be about 98 % efficient at this 0.295 CA current discharge.

2:22 mins timestamp

Load turned off. Cell immediately rises to 3.254v @ 0 amps.

2:30 mins timestamp

“This is a good cell”.

I would not use this cell.

3:02 mins timestamp

40 secs from off, Instrument reads 3.271v, has some self heating overpotential voltage reduction.

3.271 – 3.028v = 243 mV of recovery in 40 seconds.

“This is something we would sell”

This is a very poor, and very used, cell.

‘Grade A vs Grade B 280ah cells lab test’ video

The Ugly:

#2 gauge welding cable 3.5 to 4 foot long pair with 150 amp Anderson Connector

No remote sensing cell voltage so cable loss drops displayed in voltage readout.

4 feet (x2) #2 welding cable about 1.4 milliohms. Anderson connector approx. 0.1 milliohms, instrument lugs about 0.2 milliohms

Total cable + connectors resistance about 1.7 milliohms.

1:25 mins timestamp

First battery test OCV = 3.283v, about 40% SOC. Used cell.

1:40 mins timestamp

Turned on 250 watt load.

Instrument immediately drops to 2.735v @ 91.413amps (250.00 watts, 0.33 CA discharge

Adjusted for 0.155v cable loss, cell at 2.890v @ 91.413amps (0.33 CA) ), 264.2 watts from battery

Battery initial Rs = 3.283v - 2.890v = 0.393v, /91.413A = 4.3 milliohms initial Rs drop. Very bad. Should be like 0.40 milliohms. About 10x worse than newer cell. Compare to first video with SFK260HP battery.

0.393v * 91.413A = 35.93 watts loss for 264.2 watts delivered, 86.4% efficiency. This is very poor.

2:21 mins timestamp

44 secs of load, not at equilibrium yet.

Instrument 3.028v @ 82.571 amps after 35 second with load. He says warming up, really? Ion diffusion is so bad at room temp it needs to get above room temp to get more ion flow. Imagine how this cell would perform at cooler temps. Your inverter may shut off for low batt voltage preventing battery warmup current from occurring.

Adjusted for 0.140v cable loss, cell at 3.168v @ 82.571 amps (0.30 CA), 261.6 watts from battery.

3.283v-3.168v = 0.115v, /82.571A = 1.39 milliohm Rs. Improved due to cell internal heating but still very poor cell.

0.115v * 82.571A = 9.5 watts loss for 261.6 watts delivered, 96.4% efficient @ 0.295 CA discharge rate. A good cell should be about 98 % efficient at this 0.295 CA current discharge.

2:22 mins timestamp

Load turned off. Cell immediately rises to 3.254v @ 0 amps.

2:30 mins timestamp

“This is a good cell”.

I would not use this cell.

3:02 mins timestamp

40 secs from off, Instrument reads 3.271v, has some self heating overpotential voltage reduction.

3.271 – 3.028v = 243 mV of recovery in 40 seconds.

“This is something we would sell”

This is a very poor, and very used, cell.

Last edited:

There will also be loss from battery terminal to cable lug connection which is not perfectly repeatable from each test cell. That why Vsense probes have to be placed on battery terminal directly, not to be influenced by cable lug current at all. Not to mention the quality of crimps on all these connectors.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

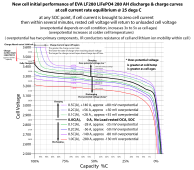

The other video ‘SFK-260 vs SFK-260HP Watt Testing’ show what good cells should test at. They are cherry-picking for their higher priced 'HP' version of battery.

‘SFK-260 vs SFK-260HP Watt Testing’ video

The good battery.

Test Instrument ‘Tonghui’ HP8182 DC Electronic Load

12v battery, SFK-260HP. Likely 280AH used cells they are giving 260 AH derating. Same 54 lbs weight between 280 AH model and 260 AH model indicating use of used cells with some derating for used cells. As mentioned in video, the ‘HP’ model has better quality selected cells for its build.

Approx. 3.5 to 4 ft #2 welding cable pair + 150 amp Anderson connector + BMS for total resistance drop to tester. No remote voltage sense used on tester to battery terminals (sense connection would still have BMS resistance). 4 ft #2 welding cable + Anderson connection is about 1.6 milli-ohms resistance to instrument. Estimated BMS and internal battery wiring is about 3-3.8 milli-ohms. Total cable, connectors, and BMS and internal wiring would be about 4.6 – 5.4 milliohms.

They have written their own PC BMS application with BT link to BMS. Looks like JDS BMS.

PC BMS application shows individual cells as read by BMS, but only to two decimal points, 10 mV resolution. Test instrument voltage readings have cable and BMS loss. BMS cell readings have direct cell voltage readings.

1:06 timestamp

All cells at start at 3.32v per BMS readout with no load, approx. 70% SOC, top balanced. Battery reads OCV on instrument of 13.286v/4 = 3.3215v per cell. Instrument matches BMS readout with no load.

1:21 timestamp

600 watt load applied.

Instrument shows 600 watts 12.986v @ 46.190A.

Estimate actual battery cells at 12.986v + (46.2 amps X 5 milliohms) = 13.217v, /4 = 3.304v/cell.

3.3215v-3.304v = 0.0175v , /46.19A = 0.38 milliohm Rs per cell. 0.38 milliohm cell Rs seems a little high.

Another way to estimate cable, connector, and BMS loss. Assume about 0.30 milliohm Rs per cell x 4 =1.2 milliohms for 4 cells.

13.286v – 12.986v = 0.300v, /46.2 amps = 6.5 milliohm – 1.20 milliohms for cells = 5.3 milliohms total cable, connectors and BMS drop. 5.3 milliohms for Cable, connectors, BMS/internal wiring looks fair. Will use this when only instrument reading is shown without actual BMS cell readings. BMS resistance will rise 30-40% when it gets hot with high current.

1.33 timestamp

With 46.2 amps, BMS shows 619.93 watts. 3.30v each cell. X 4 = 13.20 vdc total (higher than instrument which has wires and BMS voltage drop included and 10 seconds of decay time into overpotential terminal voltage slump.

1.45 timestamp

54 seconds since load applied, should be about 70% of leveled out equilibrium voltage slump at cell terminal voltage slump at 46 amp load. Did not show BMS cell voltages so have to estimate based on instrument with cabling and BMS voltage drop resistance.

Instrument now shows 12.946v @ 46.330 A, 0.279 ohm Res, 0.04v Vpp, 0.3298 A Ipp.

Assuming about 5.3 milliohms (BMS MOSFET’s now warm) for cable, connectors, and BMS loss, 0.245v drop, batteries would be at 13.191v/4 = 3.298v per cell. That would be 3.322v – 3.298v = 24 mV cell terminal voltage slump at 54 seconds of load at 46.3 amps. 26 mV/60% to equilibrium = 39 mV estimate of terminal voltage drop at equilibrium. This is very good, like new cells, which would expect about 40 mV terminal voltage slump for a new 280 AH EVA cell with 46 amp load (16.4% CA loading).

1:46 timestamp

Remove load, instrument shows 13.241v, 0A. /4 = 3.3103v per cell

1:53 timestamp

Instrument shows recovery to 13.253v after 7 seconds from load stop. Still not recovered fully yet. /4 = 3.313v/cell.

1:56 timestamp

1000 watt load applied.

Instrument shows 12.752v @ 78.413A, 0.163 ohms Res, 0.04 Vpp, 0.3298 A Ipp

/4 = 3.188v per cell.

2:04 timestamp

8 seconds since 1000 watt, 78.4 amp load applied.

BMS shows all cells at 3.28v with 78 amp load current. These are well matched cells !.

Timestamp 2:24

BMS reads cells as 3.27v, 3.27, 3.27, 3.28v with 78.4 amp at 28 seconds time with load. Still well matched. These are very good cells with near new cell performance. Wish they read out cell voltage to 3 decimal points on BMS applications display. 28 secs is about 45% to equilibrium.

Overpotential terminal voltage slump from original 3.3215v – 3.27v = 51.5 mV slump at 28 seconds.

At 78.4 amps, 0.28 CA load on new 280 AH EVA cell would expect about 55 mV equilibrium slump. These are excellent cells in this battery pack.

Timestamp 2:27

Instrument reads 12.693v @ 78.774A.

31 seconds after load applied. 3 seconds after cell voltage shown to instrument shown.

BMS shows 13.09 vdc total, Instrument shows 12.692v. Looks like about 0.398 voltage drop for instrument cables, Anderson connector, and BMS. Likely BMS dominates. 0.398v/ 78.781A = 5 milliohms loss.

4 feet (x2) #2 welding cable about 1.4 milliohms, x78.8 amps = 0.110v drop. Anderson connector approx. 0.2 milliohm x 78.8 amps = 0.016v, 0.4 milliohms for instru banana plugs = 0.032v

Summing cable/connector drop = 0.110v + 0.016v + 0.0.32v = 0.158v. 13.09v-12.69v = 0.398v

0.398v-0.158v = 0.240v drop for BMS. 0.240v/78.8A = 3 milliohms for BMS and internal battery wiring. BMS MOSFET’s likely fairly warm at 79 amps so their resistance is a little elevated.

Roughly, cable, connectors, and BMS resistance is about 5 milliohms total.

Timestamp 2:32

36 second since load applied

Instrument 12.689v @ 78.802 A].

Load switched off.

Instrument reads 13.196v / 4 = 3.299 v per cell. Just beginning terminal voltage recovery.

Timestamp 3:05

33 seconds since load turned off. Not fully recovered in 33 seconds but getting close.

Recovery in 33 secs to 13.243v /4 = 3.311v per cell (started at 3.32v/cell)

Timestamp 3:07

Engage 1500 watt load.

Instru 12.472v @ 120.263A.

12.472v / 4 = 3.118 v/cell on instru with cable & BMS losses.

Cabling and BMS drop at 120 amps would be about 120 amps x 5 millohms = 0.600 v.

Series cells would be 12.472v + 0.600v = 13.07v /4 = 3.268v. Load just applied so not reached equilibrium.

3:16 timestamp

BMS shows 3.26v, 3.25v, 3.26v, 3.26v. Still well matched cells with 120 Amp load !!!

120/280AH (they are spec’g battery at 260 AH with used cells) = 0.43 CA cell load current.

3.32v original no load – 3.26v with 120 0.43 CA load = 60 mV cell drop. This is great performance.

Time since load applied is only 9 seconds so not at equilibrium.

Timestamp 3:27

“Only drawback, you are running up there. We don’t like to see for extended period of time”

This statement and only at 0.43 CA rate of current load. Matches my recommendation not to use 280 AH cells at sustained current above 0.5 CA rate. Less for used cells.

Also may have some issues with BMS heating.

Timestamp 4:37

Instrument showing 12.403v @ 120.939A. No BMS cell voltage shown so will have to estimate cell voltages from cabling and BMS losses.

Loaded for 30 secs with 120 amp. Cable, connectors, and BMS loss is 120 amps x 5 milliohms = 0.600v.

13.286v start – 0.600v = 12.686v-12.403v = 0.283v drop /4 cells = 71 mV slump per cell @ 30 secs of 120A load.

Has not reached full equilibrium in 30 seconds and BMS is probably getting hot with 120 amps of load so its resistance is going up by 30-40% of room temp resistance. BMS series MOSFET’s getting about 30-35 watts of heating. Wish he had shown BMS temp on the app.

This is very good cell terminal voltage slump for 120A load. Expect equilibrium slump for new 280 AH at 0.43 CA current of about 70 mV.

Timestamp 4:56

Turn off load

Instr 13.209v on immediate turn off recovery without recovery time. /4 = 3.302v

Conclusion: These are new or nearly new cells.

‘SFK-260 vs SFK-260HP Watt Testing’ video

The good battery.

Test Instrument ‘Tonghui’ HP8182 DC Electronic Load

12v battery, SFK-260HP. Likely 280AH used cells they are giving 260 AH derating. Same 54 lbs weight between 280 AH model and 260 AH model indicating use of used cells with some derating for used cells. As mentioned in video, the ‘HP’ model has better quality selected cells for its build.

Approx. 3.5 to 4 ft #2 welding cable pair + 150 amp Anderson connector + BMS for total resistance drop to tester. No remote voltage sense used on tester to battery terminals (sense connection would still have BMS resistance). 4 ft #2 welding cable + Anderson connection is about 1.6 milli-ohms resistance to instrument. Estimated BMS and internal battery wiring is about 3-3.8 milli-ohms. Total cable, connectors, and BMS and internal wiring would be about 4.6 – 5.4 milliohms.

They have written their own PC BMS application with BT link to BMS. Looks like JDS BMS.

PC BMS application shows individual cells as read by BMS, but only to two decimal points, 10 mV resolution. Test instrument voltage readings have cable and BMS loss. BMS cell readings have direct cell voltage readings.

1:06 timestamp

All cells at start at 3.32v per BMS readout with no load, approx. 70% SOC, top balanced. Battery reads OCV on instrument of 13.286v/4 = 3.3215v per cell. Instrument matches BMS readout with no load.

1:21 timestamp

600 watt load applied.

Instrument shows 600 watts 12.986v @ 46.190A.

Estimate actual battery cells at 12.986v + (46.2 amps X 5 milliohms) = 13.217v, /4 = 3.304v/cell.

3.3215v-3.304v = 0.0175v , /46.19A = 0.38 milliohm Rs per cell. 0.38 milliohm cell Rs seems a little high.

Another way to estimate cable, connector, and BMS loss. Assume about 0.30 milliohm Rs per cell x 4 =1.2 milliohms for 4 cells.

13.286v – 12.986v = 0.300v, /46.2 amps = 6.5 milliohm – 1.20 milliohms for cells = 5.3 milliohms total cable, connectors and BMS drop. 5.3 milliohms for Cable, connectors, BMS/internal wiring looks fair. Will use this when only instrument reading is shown without actual BMS cell readings. BMS resistance will rise 30-40% when it gets hot with high current.

1.33 timestamp

With 46.2 amps, BMS shows 619.93 watts. 3.30v each cell. X 4 = 13.20 vdc total (higher than instrument which has wires and BMS voltage drop included and 10 seconds of decay time into overpotential terminal voltage slump.

1.45 timestamp

54 seconds since load applied, should be about 70% of leveled out equilibrium voltage slump at cell terminal voltage slump at 46 amp load. Did not show BMS cell voltages so have to estimate based on instrument with cabling and BMS voltage drop resistance.

Instrument now shows 12.946v @ 46.330 A, 0.279 ohm Res, 0.04v Vpp, 0.3298 A Ipp.

Assuming about 5.3 milliohms (BMS MOSFET’s now warm) for cable, connectors, and BMS loss, 0.245v drop, batteries would be at 13.191v/4 = 3.298v per cell. That would be 3.322v – 3.298v = 24 mV cell terminal voltage slump at 54 seconds of load at 46.3 amps. 26 mV/60% to equilibrium = 39 mV estimate of terminal voltage drop at equilibrium. This is very good, like new cells, which would expect about 40 mV terminal voltage slump for a new 280 AH EVA cell with 46 amp load (16.4% CA loading).

1:46 timestamp

Remove load, instrument shows 13.241v, 0A. /4 = 3.3103v per cell

1:53 timestamp

Instrument shows recovery to 13.253v after 7 seconds from load stop. Still not recovered fully yet. /4 = 3.313v/cell.

1:56 timestamp

1000 watt load applied.

Instrument shows 12.752v @ 78.413A, 0.163 ohms Res, 0.04 Vpp, 0.3298 A Ipp

/4 = 3.188v per cell.

2:04 timestamp

8 seconds since 1000 watt, 78.4 amp load applied.

BMS shows all cells at 3.28v with 78 amp load current. These are well matched cells !.

Timestamp 2:24

BMS reads cells as 3.27v, 3.27, 3.27, 3.28v with 78.4 amp at 28 seconds time with load. Still well matched. These are very good cells with near new cell performance. Wish they read out cell voltage to 3 decimal points on BMS applications display. 28 secs is about 45% to equilibrium.

Overpotential terminal voltage slump from original 3.3215v – 3.27v = 51.5 mV slump at 28 seconds.

At 78.4 amps, 0.28 CA load on new 280 AH EVA cell would expect about 55 mV equilibrium slump. These are excellent cells in this battery pack.

Timestamp 2:27

Instrument reads 12.693v @ 78.774A.

31 seconds after load applied. 3 seconds after cell voltage shown to instrument shown.

BMS shows 13.09 vdc total, Instrument shows 12.692v. Looks like about 0.398 voltage drop for instrument cables, Anderson connector, and BMS. Likely BMS dominates. 0.398v/ 78.781A = 5 milliohms loss.

4 feet (x2) #2 welding cable about 1.4 milliohms, x78.8 amps = 0.110v drop. Anderson connector approx. 0.2 milliohm x 78.8 amps = 0.016v, 0.4 milliohms for instru banana plugs = 0.032v

Summing cable/connector drop = 0.110v + 0.016v + 0.0.32v = 0.158v. 13.09v-12.69v = 0.398v

0.398v-0.158v = 0.240v drop for BMS. 0.240v/78.8A = 3 milliohms for BMS and internal battery wiring. BMS MOSFET’s likely fairly warm at 79 amps so their resistance is a little elevated.

Roughly, cable, connectors, and BMS resistance is about 5 milliohms total.

Timestamp 2:32

36 second since load applied

Instrument 12.689v @ 78.802 A].

Load switched off.

Instrument reads 13.196v / 4 = 3.299 v per cell. Just beginning terminal voltage recovery.

Timestamp 3:05

33 seconds since load turned off. Not fully recovered in 33 seconds but getting close.

Recovery in 33 secs to 13.243v /4 = 3.311v per cell (started at 3.32v/cell)

Timestamp 3:07

Engage 1500 watt load.

Instru 12.472v @ 120.263A.

12.472v / 4 = 3.118 v/cell on instru with cable & BMS losses.

Cabling and BMS drop at 120 amps would be about 120 amps x 5 millohms = 0.600 v.

Series cells would be 12.472v + 0.600v = 13.07v /4 = 3.268v. Load just applied so not reached equilibrium.

3:16 timestamp

BMS shows 3.26v, 3.25v, 3.26v, 3.26v. Still well matched cells with 120 Amp load !!!

120/280AH (they are spec’g battery at 260 AH with used cells) = 0.43 CA cell load current.

3.32v original no load – 3.26v with 120 0.43 CA load = 60 mV cell drop. This is great performance.

Time since load applied is only 9 seconds so not at equilibrium.

Timestamp 3:27

“Only drawback, you are running up there. We don’t like to see for extended period of time”

This statement and only at 0.43 CA rate of current load. Matches my recommendation not to use 280 AH cells at sustained current above 0.5 CA rate. Less for used cells.

Also may have some issues with BMS heating.

Timestamp 4:37

Instrument showing 12.403v @ 120.939A. No BMS cell voltage shown so will have to estimate cell voltages from cabling and BMS losses.

Loaded for 30 secs with 120 amp. Cable, connectors, and BMS loss is 120 amps x 5 milliohms = 0.600v.

13.286v start – 0.600v = 12.686v-12.403v = 0.283v drop /4 cells = 71 mV slump per cell @ 30 secs of 120A load.

Has not reached full equilibrium in 30 seconds and BMS is probably getting hot with 120 amps of load so its resistance is going up by 30-40% of room temp resistance. BMS series MOSFET’s getting about 30-35 watts of heating. Wish he had shown BMS temp on the app.

This is very good cell terminal voltage slump for 120A load. Expect equilibrium slump for new 280 AH at 0.43 CA current of about 70 mV.

Timestamp 4:56

Turn off load

Instr 13.209v on immediate turn off recovery without recovery time. /4 = 3.302v

Conclusion: These are new or nearly new cells.

Last edited:

Please link to your video of the correct way to test these cells, and also to your company website. Thanks!I did not at first. I saw it up to 200A part. That cell is weak but all that boasting and incorrect testing method is LOL. And his insistence that he is testing the power a cell can provide is a fail.

LOL. All you need to do is to set same load current for both cells. I don't have a company web site, im just an amateur. Maybe i can start my own youtube page and be like Will Prowse, hmmPlease link to your video of the correct way to test these cells, and also to your company website. Thanks!

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,013

grateful for technical critique and discourse about testing methodology

no input on methodology.

no input on methodology.

???no input on methodology.

?All you need to do is to set same load current for both cells. I don't have a company web site, im just an amateur.

I think we found SFK's lurker account. ?Please link to your video of the correct way to test these cells, and also to your company website. Thanks!

AKvalleyguy

Solar Enthusiast

- Joined

- Nov 21, 2021

- Messages

- 143

Whoever the person is, seems he/she is trying to get AntronX banned by telling him to link a company website.I think we found SFK's lurker account. ?

I'm considering building an SFK kit and wanted to test theWhoever the person is, seems he/she is trying to get AntronX banned by telling him to link a company website.

credibility of this claim of the SFK guy having "no clue".

A guy willing to risk it all in a business venture, put out his own YT videos,

and whose name and address are known to the public seems a lot

more credible than an anonymous critic and self-proclaimed

amateur who's probably never run a company in his life.

One man's opinion.

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,833

Here is SFK updated video but still not done right. They need to learn how to use test equipment properly.

They also twice said that the v-sense input measures the resistance of the wires! WTF!

Having expensive test equipment without knowing how to use it properly is not good.

They also twice said that the v-sense input measures the resistance of the wires! WTF!

Having expensive test equipment without knowing how to use it properly is not good.

Last edited:

Bud Martin

Solar Wizard

- Joined

- Aug 27, 2020

- Messages

- 4,833

Andy's video.

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

Here is SFK updated video but still not done right. They need to learn how to use test equipment properly.

They also twice said that the v-sense input measures the resistance of the wires! WTF!

Having expensive test equipment without knowing how to use it properly is not good.

Cable, Anderson connector, and terminal on instrument has about 2 milliohm of resistance,

122 amps x 2 mohm should be about 0.24v drop.

Also started with OCV of 13.295v (3.324v per cell) then initially dropped to 12.352v before I*R_ionic decay effects happen.

Adding back in the 0.5 mohm x 121A for BMS resistance and internal wiring resistance 12.352v + (121A x 0.0005 ohms) = 12.4125v (3.103v per cell).

If that was true, the cells would have to have an initial (3.324v - 3.103v) = 0.221v per cell of I*R_ohmic drop, meaning R_ohmic is 0.221v/121A = 1.83 milliohms.

This is the initial, T=0 load applied, R_ohmic which should be similar to what a 1 kHz impedance meter reads for cell impedance, depending a little on instrument's sampling rate after applying load. For 280 AH EVA cell this is typically between 0.15 and 0.20 milliohms. 1.83 milliohms would be totally garbage cells.

There is obviously a setup control in instrument that was not changed to enable remote Vsense input terminals instead of using main load terminal inputs for voltage sensing. Instrument is still reading voltage on high amperage terminal inputs for voltage sensing, just as original videos.

Last edited:

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

SFK sure suckered the Gullible Andy - those two are made for each other.

Andy's smack babble is ludicrous but he is so personable & entertaining for the other gullibles that it keeps going.

Standard Issue Polyester Clad used car flogger without any real clue. Too much correction & support needed by Andy's Youtube U Victims.

Just my observations & experience vs his drivel and I will GET REPORTED for this I am certain.

Andy's smack babble is ludicrous but he is so personable & entertaining for the other gullibles that it keeps going.

Standard Issue Polyester Clad used car flogger without any real clue. Too much correction & support needed by Andy's Youtube U Victims.

Just my observations & experience vs his drivel and I will GET REPORTED for this I am certain.

wattmatters

Solar Wizard

In what way?SFK sure suckered the Gullible Andy

I watched Andy's video (linked above) and he was critical of SFK's testing.

He said SFK didn't measure voltage correctly (saying they were not using their tester correctly), nor did he believe the internal resistance values SFK quoted.

He then sought to replicate the SFK tests but he could not replicate SFK's results. Primarily because he was using the tester's voltage test leads which SFK did not. He then applied even higher current loadings and used batches of cells at different SOC. Still unable to replicate SFKs results.

I'm less clear on the validity of the IR testing Andy performed but that's really a moot point if the current is being delivered without much in the way of voltage sag.

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

I have not been able to watch Andy's vids in a while but I did a few recent ones painfully which made me cringe to the point of Upchucking.In what way?

I watched Andy's video (linked above) and he was critical of SFK's testing.

He said SFK didn't measure voltage correctly (saying they were not using their tester correctly), nor did he believe the internal resistance values SFK quoted.

He then sought to replicate the SFK tests but he could not replicate SFK's results. Primarily because he was using the tester's voltage test leads which SFK did not. He then applied even higher current loadings and used batches of cells at different SOC. Still unable to replicate SFKs results.

I'm less clear on the validity of the IR testing Andy performed but that's really a moot point if the current is being delivered without much in the way of voltage sag.

As for SFK, there is MUCH that many do not know and I won't share , except to say he developed a Very Bad Rep with vendors & manufacturers and essential got black listed by many. That is ALL I will say on that.

No further discussion on either Andy or SFK.