I searched the net and read a number of posts but nothing gave me a clear ok to go ahead so I thought I'd sign up, say Hi and ask my first question.

About three years into owning this system, it started having problems. The installer eventually left me hanging so now I'm wanting to learn what ever I can about it so I can maintain it myself.

At the time, I wasn't aware enough to know that I had gotten a grid tied system so the two things I'd like to do are to first fix the system and second, add some hardware so I can run this even when there are grid outages.

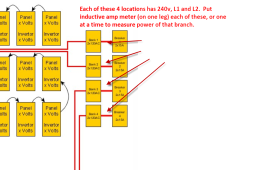

Step one is to test all of the inverters. Since it's a grid tied system, so long as the grid panel breakers are on, there is always 120VAC on each side.

If I understand correctly, to test, I have to turn off the breakers, then disconnect the inverters from the panel, inject voltage and see if I get a reasonable output.

The inverters are Pantheon II, Integrated, Microinverter, p250lv-208/240, 48V version.

Recommended STC Module input Power rating: 235 W – 280 W

Maximum Continuous input Power: 250 W

Maximum input voltage: 48 v

MPPT voltage range: 18 v – 37 v

Maximum Power voltage range: 25 v – 37 v

My question is, what exactly do I need as a 48V power supply to test these inverters?

I read a bunch of posts and it seems I need to use a range within the MPPT and not 48VDC.

Initially, I thought I should use a 48VDC supply around around 3 Amps to keep it under the 250 Watt max input.

About three years into owning this system, it started having problems. The installer eventually left me hanging so now I'm wanting to learn what ever I can about it so I can maintain it myself.

At the time, I wasn't aware enough to know that I had gotten a grid tied system so the two things I'd like to do are to first fix the system and second, add some hardware so I can run this even when there are grid outages.

Step one is to test all of the inverters. Since it's a grid tied system, so long as the grid panel breakers are on, there is always 120VAC on each side.

If I understand correctly, to test, I have to turn off the breakers, then disconnect the inverters from the panel, inject voltage and see if I get a reasonable output.

The inverters are Pantheon II, Integrated, Microinverter, p250lv-208/240, 48V version.

Recommended STC Module input Power rating: 235 W – 280 W

Maximum Continuous input Power: 250 W

Maximum input voltage: 48 v

MPPT voltage range: 18 v – 37 v

Maximum Power voltage range: 25 v – 37 v

My question is, what exactly do I need as a 48V power supply to test these inverters?

I read a bunch of posts and it seems I need to use a range within the MPPT and not 48VDC.

Initially, I thought I should use a 48VDC supply around around 3 Amps to keep it under the 250 Watt max input.