I´ve Been down that rabbit hole before.

Silicon Wire Is really nice and flexible, not only it resist temperature up to 200celcious, but also insulate its surrounding from that heat. Those are great attributes and highly sought after in some applications. Like Battery Making.

I also tested running a 1600Watt 12v inverter with a single 8AWG. It works, but with 140 Amps going through, the wire just gets too hot for the touch. >60c.

You can see BMS that come with leads are usually Silicone wire. Because they allow the flexibility for bulding inside a battery case.

There is one application that I use Silicon Wire allot, which is Short Burst of Amps to Crank an Engine. In that situation, the exposure to high Amps is so Short, that the Silicone Wire Virtually acts like a Busbar, for a fraction of a second.

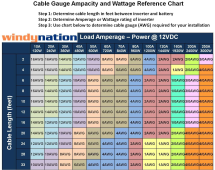

Remember that when Calculating the AWG size you need you have to take into account:

- Insulation rating in Celcious: 60c, 90c, 105c

- Continous Amps going through AND

- Lenght of wire

- Material: Copper of course

So, there are dozens of tables showing you ampacity based on diferent factors, most are a variation of the above.

So that is why a 10AWG DC 1inch for interconection in batteries is rated @50Amps and at 28 feet in your house AC Breaker is rated @ 20 Amps.

My rule of thumb with silicone wire is Derate it 50% and then double up the wire. (my runs are never over 2 feet).

I cover them with Braided Fiberglass sleeve

This is my conlusion, based on my necesities.

That is my grain of salt. Hope it helps someone.

Regards

2 X 8AWG Silicon Wire on each interconnect. Braided Fiberglass sleeve.

View attachment 98709

View attachment 98708