Delmar

Solar Addict

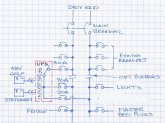

Humor me on this one. The intent is how to isolate critical/grid-down circuits in an existing breaker panel without major surgery to the wall, and safely isolate backup-power from grid power. And be reversible should I ever sell the house.

I have a 3000VA UPS being used as a grid-down inverter that back-feeds the panel. The UPS has an integral transfer switch and float charger that are currently not being used. I have a golf cart with 48V mobile battery set, and planning to purchase a 2nd 48V stationary battery set.

My existing breaker panel is only around 50% capacity. How dangerous would it be to cut the existing bus bars midway-panel and move any critical circuits (fridge, lights, master bedroom plugs) to the lower part of the panel? Then critical circuits would be constantly powered through the UPS, and safer than my manually sequencing the breakers. Please reference the following sketch.

During grid-down would allow me to have one battery set inside powering the house, and one set outside charging from the panels. Can also lift the UPS onto the cart and drive to a nearby family home and briefly power their fridge.

I have a 3000VA UPS being used as a grid-down inverter that back-feeds the panel. The UPS has an integral transfer switch and float charger that are currently not being used. I have a golf cart with 48V mobile battery set, and planning to purchase a 2nd 48V stationary battery set.

My existing breaker panel is only around 50% capacity. How dangerous would it be to cut the existing bus bars midway-panel and move any critical circuits (fridge, lights, master bedroom plugs) to the lower part of the panel? Then critical circuits would be constantly powered through the UPS, and safer than my manually sequencing the breakers. Please reference the following sketch.

During grid-down would allow me to have one battery set inside powering the house, and one set outside charging from the panels. Can also lift the UPS onto the cart and drive to a nearby family home and briefly power their fridge.