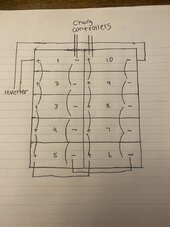

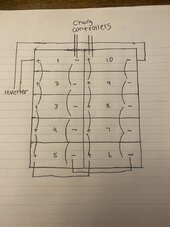

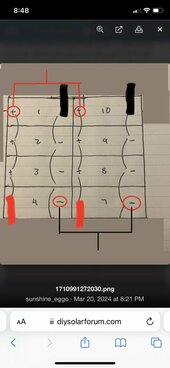

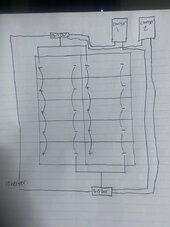

Just a quick suggestion here, you have 10 batteries in parallel. That means you can draw around 1000amps from them like that (100amps each). when you switch to 48v you will be able to draw 200amps (100 from each parallel bank) 8 in parallel means 800amps.

Assumption is that your batteries have 100amp BMS in them.,

You will need beefy bus bars that can carry the current.

For the 1000amp configuration you are looking at pure copper bars 1.5in x 1/4in = 1200amps (20% safety margin)

For 1000amps in brass you need something like 1in x 7/8in ... or 1.5in x 5/8in.... = 1200amps

Those bus bars will be pretty expensive if you buy them pre-built, but you can order the copper and make your own without to much trouble for a lot less money.

Math behind that - width * height in millimeters * 4.97amps for copper or 2.1amps for brass --

NOTE - poor quality brass has less copper and costs less but the factor I've been using for it is only 1.2amps -- most vendors sell nickle plated brass because it is cheaper but if I were making my own I would stick to copper.

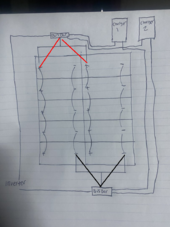

Switch to the 48v configuration now and you can reduce those sizes way down and save some $$.

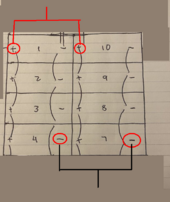

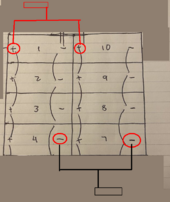

Now for the suggestion - I woud put 125amp MRBF fuses and holders on the positive post of each of those batteries then a class T between the bus bar and the inverter. Size the class T to your expected load + 25%. And that connecting wire will also be sized the same way.

The MRBF fuses protect the batteries from each other if one goes nuts and dumps current. They also protect you from a short between bus bars as they would each blow in "short" order. pun intended. But seriously a dropped screwdriver at those currents could mean molten metal everywhere.

Beyond that rubber boots on all connections would be good unless the setup is in a sealed enclosed space. I think they are good everywhere but opinions vary.