offthetop04

New Member

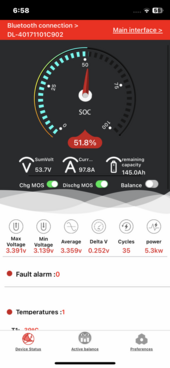

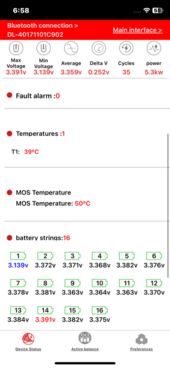

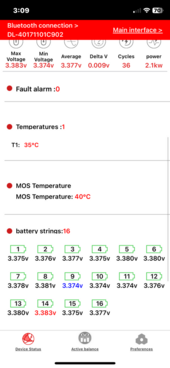

Woke up to this this morning.

Disconnected the busbars and the #1 cells read 3.30v. When I was re-installing the busbars I stripped the thread of the #1 cell.

The nut is somewhat snug but not tight.

Any advice on where to start would be extremely appreciated.

48volt 280ah 16s battery pack.

Daly 250amp BMS

Daly active balancer.

I disconnected everything and reconnected and it didn’t do anything different.

Disconnected the busbars and the #1 cells read 3.30v. When I was re-installing the busbars I stripped the thread of the #1 cell.

The nut is somewhat snug but not tight.

Any advice on where to start would be extremely appreciated.

48volt 280ah 16s battery pack.

Daly 250amp BMS

Daly active balancer.

I disconnected everything and reconnected and it didn’t do anything different.