iClick

New Member

G'day DIY brains trust.

Long story short, I have a 135Ah - 12 V battery consisting of 32 33140 cells in a 4S8P configuration.

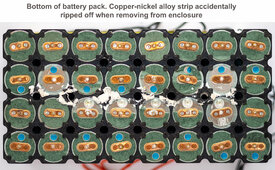

The original battery had shorted and fried the BMS. I was removing the pack from the battery enclosure and in the process I manage to unfortunately tear the bottom nickel sheets away from the cells. I had no idea that the nickel sheet wask was directly glued to the enclosure until it was too late. Fortunately all these cells are reading exactly 3.32 V and appear in good shape however I now need to reattach a new nickel sheet to the cells so I will have a working battery again. Best visually explained in this gallery

I am a novice in building batteries but I'm willing to give anything a crack. If spot welding is the better solution then I would consider using this post as a DIY option for inspiration to build a spot welder. For the nickel sheets I was looking at something along these lines. C7701 Copper-nickel alloy strip EDIT: What thickness nickle-plate would be recommended considering the total power is 135Ah

If soldering is a better option, then I am open to suggestions on what would be best practice.

Thanks for any tips in helping me make good my small disaster!

EDIT: Picture of terminals

Long story short, I have a 135Ah - 12 V battery consisting of 32 33140 cells in a 4S8P configuration.

The original battery had shorted and fried the BMS. I was removing the pack from the battery enclosure and in the process I manage to unfortunately tear the bottom nickel sheets away from the cells. I had no idea that the nickel sheet wask was directly glued to the enclosure until it was too late. Fortunately all these cells are reading exactly 3.32 V and appear in good shape however I now need to reattach a new nickel sheet to the cells so I will have a working battery again. Best visually explained in this gallery

I am a novice in building batteries but I'm willing to give anything a crack. If spot welding is the better solution then I would consider using this post as a DIY option for inspiration to build a spot welder. For the nickel sheets I was looking at something along these lines. C7701 Copper-nickel alloy strip EDIT: What thickness nickle-plate would be recommended considering the total power is 135Ah

If soldering is a better option, then I am open to suggestions on what would be best practice.

Thanks for any tips in helping me make good my small disaster!

EDIT: Picture of terminals

Last edited: