I just received these three new Hamassi 100Ah batteries with Bluetooth that I plan to run in series. They arrived at 0% state of charge. I charged them to 100% on their own independent 10amp charging banks and below are the specs the Bluetooth app shows me after charging to 100% and sitting for 5 hours.

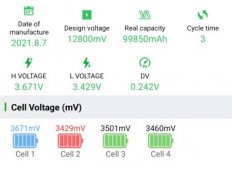

Battery 1's Bluetooth is stating a real capacity of 97.7Ah, which is concerning. How accurate is the Bluetooth real capacity reading?

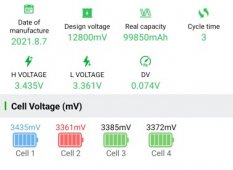

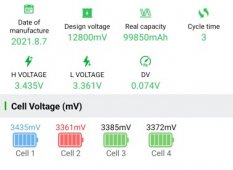

When it was fully charged and the charger was still connected it showed high cell at 3700mV and low cell at 3435mV with a deviation of .265V. Since stopping the charge those two cells have settled to 3495mV and 3373mV with a deviation of .122V.

Also, the state of charge on battery 1 fell to 99% within 6 hours after charging, while the other two batteries remain at 100%.

Does anyone see anything that I should be concerned about? Should I check anything else, run any other tests, or do anything further? How will these batteries perform in series with these differences in specs between the 3?

I have a capacity load tester ordered but it won't arrive for a couple of weeks.

Battery (1)

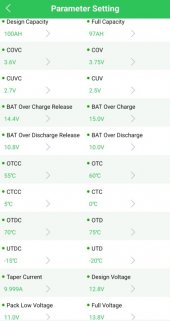

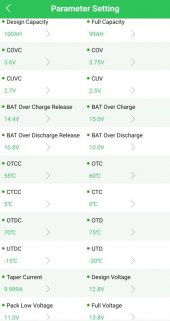

Battery (2)

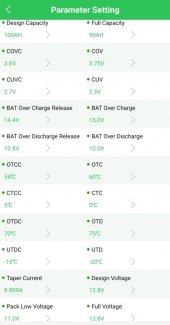

Battery (3)

Battery 1's Bluetooth is stating a real capacity of 97.7Ah, which is concerning. How accurate is the Bluetooth real capacity reading?

When it was fully charged and the charger was still connected it showed high cell at 3700mV and low cell at 3435mV with a deviation of .265V. Since stopping the charge those two cells have settled to 3495mV and 3373mV with a deviation of .122V.

Also, the state of charge on battery 1 fell to 99% within 6 hours after charging, while the other two batteries remain at 100%.

Does anyone see anything that I should be concerned about? Should I check anything else, run any other tests, or do anything further? How will these batteries perform in series with these differences in specs between the 3?

I have a capacity load tester ordered but it won't arrive for a couple of weeks.

Battery (1)

Battery (2)

Battery (3)

Attachments

Last edited: