KevinC_63559

New Member

First, let me thank everyone who has contributed to my slew of questions under other threads: THANK YOU!

Currently looking to sanity check cabling sizes from my batteries to a (for purposes of this discussion) Victron MultiPlus Compact 2000/80.

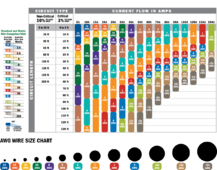

So... clearly if the charger is pumping 80 amps, I need at least 4AWG wire. I'm presuming I have at least that much right <smile>.

If I maxed the inverter out at 2000VA @ 12V, that divides down to 167 amps. But the inverter is only 92% efficient, so really 181 amps. That implies to me I should wire the batteries with 2/0 wire?

Of course, the BMS will cut off at 100amp for my current 12V100A LiFePO4 battery, which implies I need at least 2 batteries in parallel to fully power this guy (or one 285ish amp one) if I want to pull full power. Correct?

Sizes above presume copper, but what about Copper Clad Aluminum (CCA)? Should I avoid that? Is there a general rule like "Never cheap out on cables"? <smile>

Thinking it would be easy enough to crimp my own connections, allow me some flexibility. Hate it when I plan like crazy and end up with cables 2 inches too short... Is crimping vs. soldering considered acceptable. Obviously could solder, just take a bit longer with the risk of melting insulation.

As always, appreciate the feedback.

ps. After writing this it occurs to me that if I'm going to need two batteries anyhow, life would become simpler to just buy a 24V unit. That would cut all amperages in half, allowing for 2 AWG wire instead of 2/0 (welding cable) wire. Then instead of providing my bench with 12V power direct from the battery bus, I'd have to use a 12V bench supply - but that is acceptable.

Currently looking to sanity check cabling sizes from my batteries to a (for purposes of this discussion) Victron MultiPlus Compact 2000/80.

So... clearly if the charger is pumping 80 amps, I need at least 4AWG wire. I'm presuming I have at least that much right <smile>.

If I maxed the inverter out at 2000VA @ 12V, that divides down to 167 amps. But the inverter is only 92% efficient, so really 181 amps. That implies to me I should wire the batteries with 2/0 wire?

Of course, the BMS will cut off at 100amp for my current 12V100A LiFePO4 battery, which implies I need at least 2 batteries in parallel to fully power this guy (or one 285ish amp one) if I want to pull full power. Correct?

Sizes above presume copper, but what about Copper Clad Aluminum (CCA)? Should I avoid that? Is there a general rule like "Never cheap out on cables"? <smile>

Thinking it would be easy enough to crimp my own connections, allow me some flexibility. Hate it when I plan like crazy and end up with cables 2 inches too short... Is crimping vs. soldering considered acceptable. Obviously could solder, just take a bit longer with the risk of melting insulation.

As always, appreciate the feedback.

ps. After writing this it occurs to me that if I'm going to need two batteries anyhow, life would become simpler to just buy a 24V unit. That would cut all amperages in half, allowing for 2 AWG wire instead of 2/0 (welding cable) wire. Then instead of providing my bench with 12V power direct from the battery bus, I'd have to use a 12V bench supply - but that is acceptable.

Last edited: