I have been charging my 24v system 8 cell system via a generator as my charge controller went out. I have a power supply plugged into the generator and the power supply ground lead hooked into where the BMS ground would go into the charge controller. Positive going to the main positive on the battery pack.

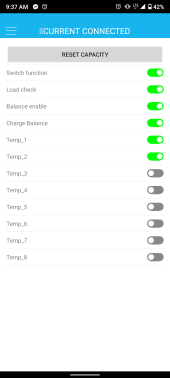

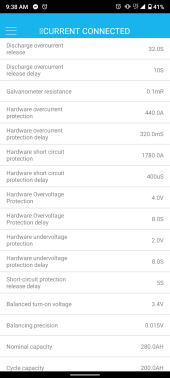

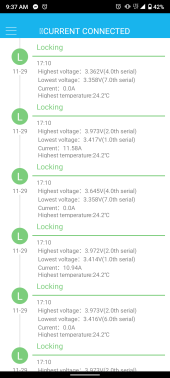

Now when I was charging these at home using the same method it all went very smoothly, no power cuts or anything. Now when I'm using the generator (predator 1100) I can see the BMS going into charge protection every few seconds. Since the load changes it changes the revs of the generator. I can see the volts/amps/watts on the power supply drop to almost zero, then the charge protect kicks off for maybe ten seconds then repeats itself forever. I know I changed some of my BMS settings so I'm wondering if I did something incorrectly? The generator should have more than enough power to run the power supply. Power supply only has a max of 10-11 amps.

Now when I was charging these at home using the same method it all went very smoothly, no power cuts or anything. Now when I'm using the generator (predator 1100) I can see the BMS going into charge protection every few seconds. Since the load changes it changes the revs of the generator. I can see the volts/amps/watts on the power supply drop to almost zero, then the charge protect kicks off for maybe ten seconds then repeats itself forever. I know I changed some of my BMS settings so I'm wondering if I did something incorrectly? The generator should have more than enough power to run the power supply. Power supply only has a max of 10-11 amps.