Kurt_

New Member

Hi all,

New to solar. I don't have any experience in this field but I am a competent engineer.

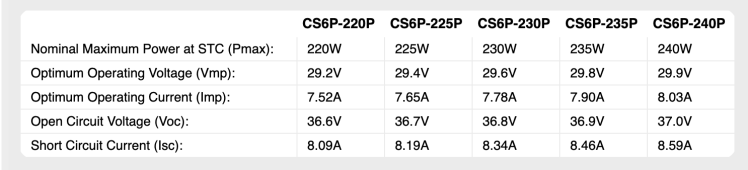

I recently purchased a 10 year old solar system: 29 each of Canadian Solar CS6-220P 220W panels and Enphase M190 microinverters (15 of the old all-metal ones and 15 newer metal/black plastic inverters)

I am interested in building a low-cost grid-tied system compliant with NEC 2020 (Actually, CSA 22.3 No 9:2020). However the micro-inverters are only compliant with UL1741/IEEE1547 and can't be grandfathered in.

In a nutshell, I want to know what I can do to bring the old Enphase M190 microinverters into compliance so I can get ESA approval to tie in to the grid.

What's the best way to go about this?

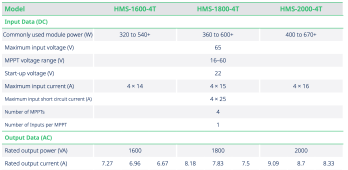

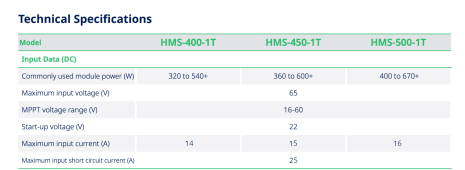

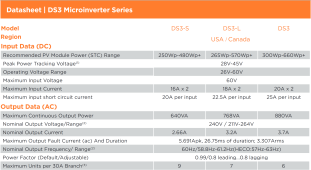

- New inverters? What's cost effective and 2020 compliant? I'm eyeing APsystems DS3-S or Hoymiles HMS-1600-4T-NA. They can be cheap - if they fail I have the Enphase ones for backup.

- Power optimizer with RSS that is compatible with microinverters?

- Standalone rapid shutdown system?

Here's my proposed setup: https://api.opensolar.com/share/1182312/?token=AA8sJ4FDuQRi7q2DejY

New to solar. I don't have any experience in this field but I am a competent engineer.

I recently purchased a 10 year old solar system: 29 each of Canadian Solar CS6-220P 220W panels and Enphase M190 microinverters (15 of the old all-metal ones and 15 newer metal/black plastic inverters)

I am interested in building a low-cost grid-tied system compliant with NEC 2020 (Actually, CSA 22.3 No 9:2020). However the micro-inverters are only compliant with UL1741/IEEE1547 and can't be grandfathered in.

In a nutshell, I want to know what I can do to bring the old Enphase M190 microinverters into compliance so I can get ESA approval to tie in to the grid.

What's the best way to go about this?

- New inverters? What's cost effective and 2020 compliant? I'm eyeing APsystems DS3-S or Hoymiles HMS-1600-4T-NA. They can be cheap - if they fail I have the Enphase ones for backup.

- Power optimizer with RSS that is compatible with microinverters?

- Standalone rapid shutdown system?

Here's my proposed setup: https://api.opensolar.com/share/1182312/?token=AA8sJ4FDuQRi7q2DejY