UpWithSolar

New Member

Hello,

Question about combining strings:

System: All 385W panels with IQ8+ microinverters. Roof mounted panels, one group of 4, and one group of 9.

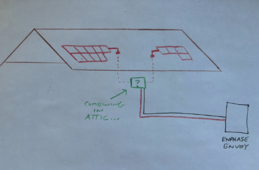

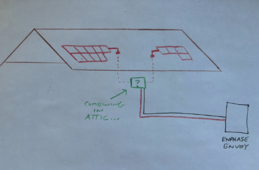

I will be combining panel strings from two different areas of the roof (see attached drawing). The combining will occur in the attic.

My plan is to run the wiring into a “junction box” in the attic, the have the combined 13 panel string homerun to the Enphase Envoy box.

For this junction box (green in the drawing) initially I was thinking I could just join the wires as if they were still in a single array on the roof. But in reading up on it, it would appear that I have to use a String Combiner Box with Fuses? Is this right? (keeping in mind all the panels are identical).

Additionally, I see that most combiner boxes have the MC4 connectors integrated - so do I switch back to those if I do use a Combiner Box? My plan is to switch from Enphase wire on the roof to 10ga THWN-2, so that's what I will have when it it hits the junction box in the attic...

I guess my biggest question is, do I need the box fused?

Thanks for advising, best regards...

Question about combining strings:

System: All 385W panels with IQ8+ microinverters. Roof mounted panels, one group of 4, and one group of 9.

I will be combining panel strings from two different areas of the roof (see attached drawing). The combining will occur in the attic.

My plan is to run the wiring into a “junction box” in the attic, the have the combined 13 panel string homerun to the Enphase Envoy box.

For this junction box (green in the drawing) initially I was thinking I could just join the wires as if they were still in a single array on the roof. But in reading up on it, it would appear that I have to use a String Combiner Box with Fuses? Is this right? (keeping in mind all the panels are identical).

Additionally, I see that most combiner boxes have the MC4 connectors integrated - so do I switch back to those if I do use a Combiner Box? My plan is to switch from Enphase wire on the roof to 10ga THWN-2, so that's what I will have when it it hits the junction box in the attic...

I guess my biggest question is, do I need the box fused?

Thanks for advising, best regards...