jakepusateri

100K Ohm Resistor

I want to build a DC direct EV charger. Not because it's practical, but because I think it'd be fun. I know people are working on commercial versions, but there's no fun in waiting around, and they all want to lock you in to their ecosystem.

Other reasons include off-grid resilience and better efficiency by not going DC->AC->DC. Or imagine an EV charging station in the middle of some area that you can't run big power to. Panels are getting cheaper by the day. Or even bringing your solar panels with you like the guy doing a solar cannonball right now (or The Martian).

Here's the high-level plan:

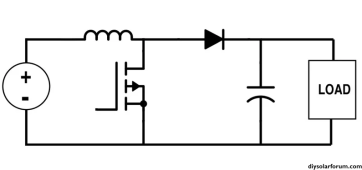

Power board - High voltage synchronous buck/boost MPPT charge controller (e.g. 500v, 30a). This will make it very efficient to convert to the ~400V of most EVs (like my Model Y). I haven't found anything like this that exists voltage-wise, so will be designing my own, mostly following the several existing designs and sourcing components rated for the higher voltages.

Control board - Pi CM4 running Everest open source EV charger software. This will handle speaking CCS to the car and high-level communication like wifi and data logging.

The boards will talk over some protocol, tbd between CAN, SPI, MOD, I2C. This will help the power board focus on being safe and not blowing things up or starting fires with up to 15kW of power since there's a full embedded linux on the other board, and a RTOS linux is not.

Optional Features that should be possible but are not immediate focus:

- passthrough to normal inverter when not charging car

- bidirectional from car (though this should work going to the mppt input of an existing inverter, like my 18kPV)

I've done a bunch of research in the past month and the idea just won't leave my brain. I took a few hardware classes in college, but I'm mostly a software guy. Anyone who wants to help would be appreciated. I'm planning on making the whole thing open source, and I'll try to keep this thread updated as well.

Other reasons include off-grid resilience and better efficiency by not going DC->AC->DC. Or imagine an EV charging station in the middle of some area that you can't run big power to. Panels are getting cheaper by the day. Or even bringing your solar panels with you like the guy doing a solar cannonball right now (or The Martian).

Here's the high-level plan:

Power board - High voltage synchronous buck/boost MPPT charge controller (e.g. 500v, 30a). This will make it very efficient to convert to the ~400V of most EVs (like my Model Y). I haven't found anything like this that exists voltage-wise, so will be designing my own, mostly following the several existing designs and sourcing components rated for the higher voltages.

Control board - Pi CM4 running Everest open source EV charger software. This will handle speaking CCS to the car and high-level communication like wifi and data logging.

The boards will talk over some protocol, tbd between CAN, SPI, MOD, I2C. This will help the power board focus on being safe and not blowing things up or starting fires with up to 15kW of power since there's a full embedded linux on the other board, and a RTOS linux is not.

Optional Features that should be possible but are not immediate focus:

- passthrough to normal inverter when not charging car

- bidirectional from car (though this should work going to the mppt input of an existing inverter, like my 18kPV)

I've done a bunch of research in the past month and the idea just won't leave my brain. I took a few hardware classes in college, but I'm mostly a software guy. Anyone who wants to help would be appreciated. I'm planning on making the whole thing open source, and I'll try to keep this thread updated as well.