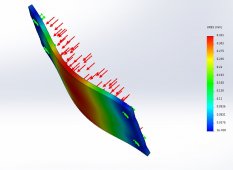

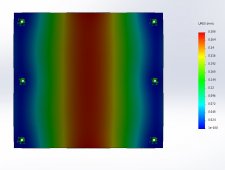

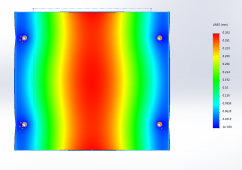

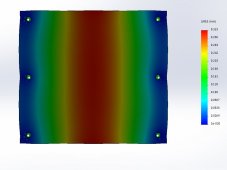

all calculations use a standard 280A size battery with 12psi of pressure. the scale to the right shows deformation in mm

with a 1/4" bolt or rod it'll need to be torqued to 8ft/lbs to achieve 12psi

assuming that plywood or OSB is stiffer than balsa, then .750 wood is comparable to .250 aluminum

personally I'm going with .750 OSB with 2" holes and silicone or rubber sheets between the cells

and now the pretty pictures

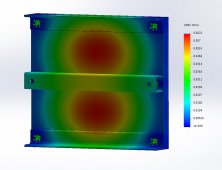

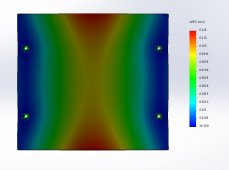

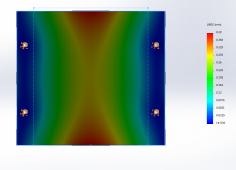

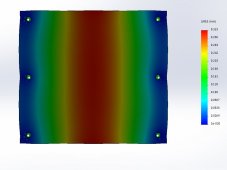

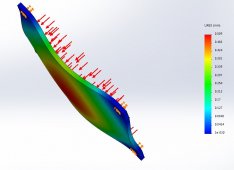

.250 aluminum (6061) with holes half an inch from the edge.

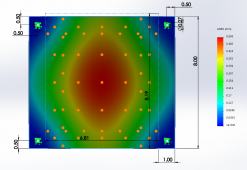

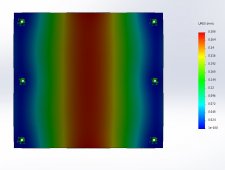

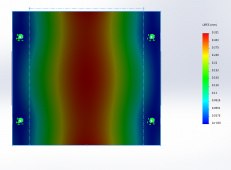

.250 aluminum with holes 1.5" from the edge

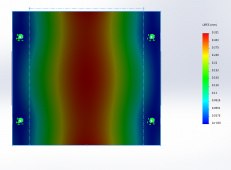

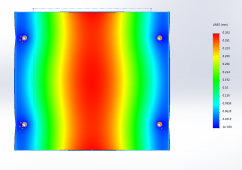

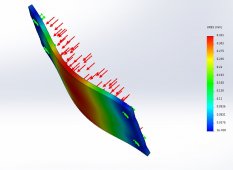

.250 aluminum with holes 2" from the edge

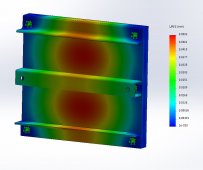

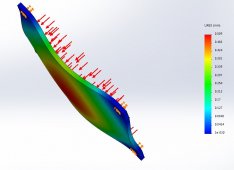

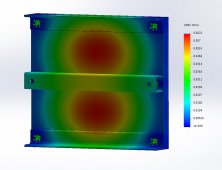

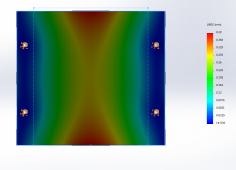

.250 aluminum with triple holes

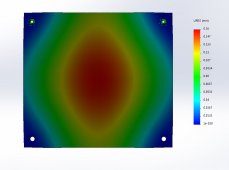

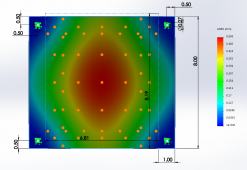

.750 wood (balsa) with holes 1.5" from the edge

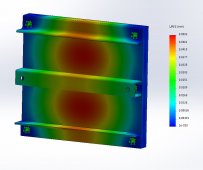

.750 wood with triple holes

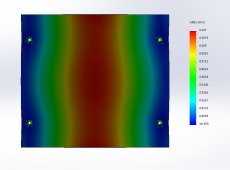

.750 wood with 1x1 steel reinforcements

with a 1/4" bolt or rod it'll need to be torqued to 8ft/lbs to achieve 12psi

assuming that plywood or OSB is stiffer than balsa, then .750 wood is comparable to .250 aluminum

personally I'm going with .750 OSB with 2" holes and silicone or rubber sheets between the cells

and now the pretty pictures

.250 aluminum (6061) with holes half an inch from the edge.

.250 aluminum with holes 1.5" from the edge

.250 aluminum with holes 2" from the edge

.250 aluminum with triple holes

.750 wood (balsa) with holes 1.5" from the edge

.750 wood with triple holes

.750 wood with 1x1 steel reinforcements