hwy17

Anti-Solar Enthusiast

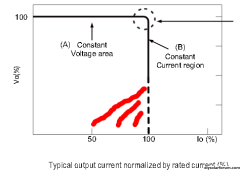

Yeah I'd get the voltage adjustable model for that reason.You definitively don't want constant current all the way to max voltage IMHO when charging the battery. We'll not when you don't know when the maximum voltage is at least.

I want to get one of the 600w above to test. I like that the charger has a higher overvoltage rating but it's fixed config 3 stage and I'd honestly rather have the on off behavior of the driver for my application of trying to backstop the bank, rather than fully charge it.