callmeburton

New Member

- Joined

- Mar 4, 2022

- Messages

- 258

Has anyone DIY'ed their pump controller and if so what did you use?

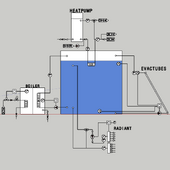

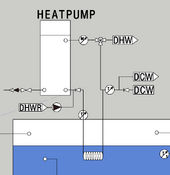

Inputs I want to monitor, log, and use to turn on / of pumps and or valves.

1) temperature at the top/bottom of the solar water tank, and at the output of the collectors.

2) temperature of water coming into an isolated DHW tank (aka ground water temp) and the temp in that tank as well.

3) flow sensor of water going to collectors, DHW use, hydronic radiant heating use, and possibly boiler use

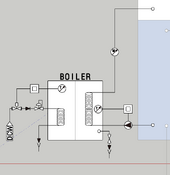

4) temperature of water going to/from boiler

5) temp sensor of water going to/from hydronic radiant heating

General logic I want to code in. (This is for a drain back system)

1) When top of tank is at 160F turn off the pump, do not turn on pump again till tank is 145F assuming the collectors are still hot enough to supply hot water to the system (this is the deadband).

2) When bottom of tank (supply to collectors) is at X degrees and the collectors are at X+Y degrees and the top of the tank is < Y degrees turn on the pump.

3) When tank temp is below 90F "call for a boiler" (the hydronic system will be directly plumbed to the thermal mass tank) ... we won't have an automated boiler so we will have to manually load / feed the boiler but an alert light would let us know without having to check apps / screens / etc. The boiler will have an exchange coil in the solar hot water tank .... less I can be convinced to directly pipe it to the tank as well.

General logic for the DHW side of the equation.

1) When ground water coming in is below tank temperature allow flow from ground water through tank coil to the DHW tank (this will likely always be allowed so it might not be needed and just plumbed up straight through the thermal mass tank)

General things I want to track in a database and visualize.

1) Hot water use in the system (flow, amount, BTU, temps in / out)

2) When the solar pump is turned on / off, flow, btu, temps in / out

3) When the boiler is used, its flow, btu, temps in / out etc.

4) overall tank top / bottom temp sensors over time

5) hydronic input / output temps / flow / btus

So for equipment I think I am looking at

1) 2 - 3 flow sensors

2) 2 - 3 pumps

3) 9 temperature sensors

4) some type of DIY controller, currently have an older phidget 8/8/8 I was thinking of using / programming / etc.

5) screen interface or web landing page for tracking / graphing etc.

Inputs I want to monitor, log, and use to turn on / of pumps and or valves.

1) temperature at the top/bottom of the solar water tank, and at the output of the collectors.

2) temperature of water coming into an isolated DHW tank (aka ground water temp) and the temp in that tank as well.

3) flow sensor of water going to collectors, DHW use, hydronic radiant heating use, and possibly boiler use

4) temperature of water going to/from boiler

5) temp sensor of water going to/from hydronic radiant heating

General logic I want to code in. (This is for a drain back system)

1) When top of tank is at 160F turn off the pump, do not turn on pump again till tank is 145F assuming the collectors are still hot enough to supply hot water to the system (this is the deadband).

2) When bottom of tank (supply to collectors) is at X degrees and the collectors are at X+Y degrees and the top of the tank is < Y degrees turn on the pump.

3) When tank temp is below 90F "call for a boiler" (the hydronic system will be directly plumbed to the thermal mass tank) ... we won't have an automated boiler so we will have to manually load / feed the boiler but an alert light would let us know without having to check apps / screens / etc. The boiler will have an exchange coil in the solar hot water tank .... less I can be convinced to directly pipe it to the tank as well.

General logic for the DHW side of the equation.

1) When ground water coming in is below tank temperature allow flow from ground water through tank coil to the DHW tank (this will likely always be allowed so it might not be needed and just plumbed up straight through the thermal mass tank)

General things I want to track in a database and visualize.

1) Hot water use in the system (flow, amount, BTU, temps in / out)

2) When the solar pump is turned on / off, flow, btu, temps in / out

3) When the boiler is used, its flow, btu, temps in / out etc.

4) overall tank top / bottom temp sensors over time

5) hydronic input / output temps / flow / btus

So for equipment I think I am looking at

1) 2 - 3 flow sensors

2) 2 - 3 pumps

3) 9 temperature sensors

4) some type of DIY controller, currently have an older phidget 8/8/8 I was thinking of using / programming / etc.

5) screen interface or web landing page for tracking / graphing etc.