You had current and voltage reported wrong. "90 amps (VOLTAGE) at 54 volts (CURRENT)" should read "54 volts (VOLTAGE) at 90 amps (CURRENT)"

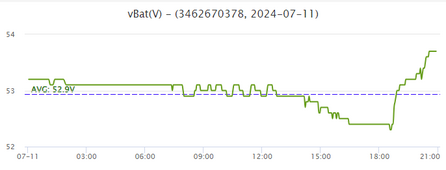

You were reporting the inverter's battery voltage readings, not the inverter's battery SOC readings, which led me to believe that you were in open-loop (voltage reading) 'communications' between the inverter and the batteries.

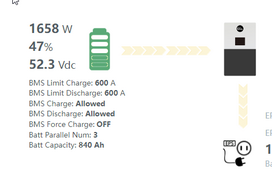

If your inverter is in closed-loop communications with the batteries, I wouldn't (in fact I don't) worry about what the voltages are. Use the SOC numbers from the inverter, the inverter will talk to the batteries and determine what they need for a voltage and charge them to whatever voltage makes the batteries happy (this will change as charging progresses).

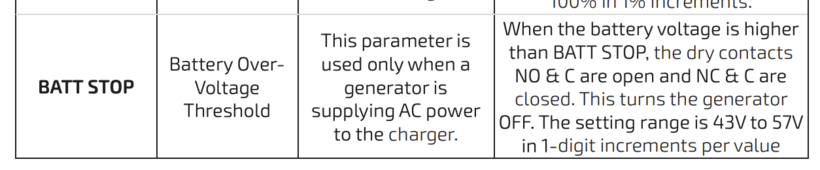

If the CV is charging the batteries based on voltage it may do something different, so you'll probably want to keep the CV voltage at 55.0V or something so as not to overcharge the batteries. I keep mine at 52V, which is sufficient to prop up the SOC to about 25% even though the CVs read 0.2 volts apart, and contribute different currents to the battery bank. I'm away for hurricane season now, so I can't make any changes, but when I get back I'll probably set the CV voltages to 55.0V and use the Gen Dry Contacts to enable the relays that power the CV AC inputs. Then I can set the 'generator' to come on at 20% and 'stop' at 40% or something. I'm working on a better control algorithm that'll probably run on the Raspberry Pi that's inside the primary inverter, so I can control charging based on weather (fully charge before hurricanes arrive, don't use grid power to charge the batteries if it's only a short time till sunrise, etc. But that's an optimization for later...