paulmurdoch

New Member

- Joined

- Dec 17, 2020

- Messages

- 36

Hello,

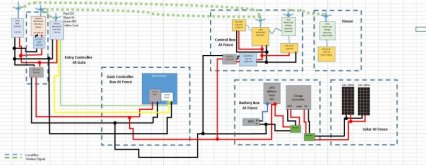

I'm looking for some expert opinions and experience from a similar setup for what I'm planning! I purchased 28 LG chem 48V 14s battery modules tested at ~75% of capacity at 2kWh.

My intention is to parallel each battery pack to give a 2S 7P and series 7 modules to give a 14S battery 48V at 15kWh. Then parallel the 4 14S 48V batteries to power my off grid vacation house.

The plan is two fold, 1) to have sufficient power for three days back up 2) to only cycle around 30% of the batteries daily so they last a great deal longer, considering the degradation what the cells already have. Been a vacation property I want to monitor and if needed adjust/remote trip/stop the system in case of an issue. For the breaker I'm thinking about a ABB breaker but I'm torn between buying separate breakers (150A) for each battery bank to enable me to remotely cut off the bank if needed or one large 300A ABB breaker for the parallel battery banks. The other issue I'm pondering is how to remotely monitor and trip/stop the system in the event of a power overload or stop charging in the event of low temperature.

I'm considering two devices either a WatchMon5 with multi mon or a Daly 200AMP BMS connected to a PC with remote access. Any advice for this set up would be most welcome.

Thank you!

I'm looking for some expert opinions and experience from a similar setup for what I'm planning! I purchased 28 LG chem 48V 14s battery modules tested at ~75% of capacity at 2kWh.

My intention is to parallel each battery pack to give a 2S 7P and series 7 modules to give a 14S battery 48V at 15kWh. Then parallel the 4 14S 48V batteries to power my off grid vacation house.

The plan is two fold, 1) to have sufficient power for three days back up 2) to only cycle around 30% of the batteries daily so they last a great deal longer, considering the degradation what the cells already have. Been a vacation property I want to monitor and if needed adjust/remote trip/stop the system in case of an issue. For the breaker I'm thinking about a ABB breaker but I'm torn between buying separate breakers (150A) for each battery bank to enable me to remotely cut off the bank if needed or one large 300A ABB breaker for the parallel battery banks. The other issue I'm pondering is how to remotely monitor and trip/stop the system in the event of a power overload or stop charging in the event of low temperature.

I'm considering two devices either a WatchMon5 with multi mon or a Daly 200AMP BMS connected to a PC with remote access. Any advice for this set up would be most welcome.

Thank you!