ScrotusGobbleBottom

Solar Enthusiast

only every otherheat shrink!!!

only every otherheat shrink!!!

I never thought of a way to short out 7 cells with a wrench before. This is something!heat shrink!!!

Yes, that's about right. This is the only aluminium profile I could get with suffiecient area to complete this task on the weekend. It was only temporary and has been disassembled after I discharded the battery again. Essentially I wanted to:What’s the clearance of those bus bars, 1/4”? That’s sketchy as shit right there.

This is only 3mm mild steel plate and ~204mm (8in) between bolts. It doesn't take "a crazy amount of pressure" to bow the middle out by about a mm, maybe 1.5mm tops.Such an odd arrangement.

Also if the plate is bowing that means crazy about of pressure on the corners of the end cells, bad mojo can happen.

That arrangement would reduce the stress on bus bars from cell expansion, but that clearance would worry me. One solution would be narrower but thicker bus bars but that creates a challenge of getting them flat on the terminal tops.

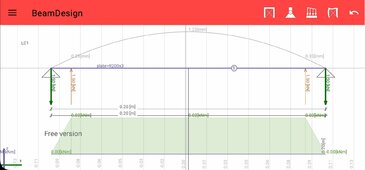

Cool little app for the bending beam force calculator.Yes, that's about right. This is the only aluminium profile I could get with suffiecient area to complete this task on the weekend. It was only temporary and has been disassembled after I discharded the battery again. Essentially I wanted to:

- charge it with a 48V inverter close to full (I did, I stopped when one of the cells reached 3.51.)

- then I set up bus bars for parallell and I topped it up all the way (to 3.59 to be exact - which still took ~4h with 30A)

- then I left it for 4h

- finally I set it up as you can see on the picture and I discharged it down to 3.2V by running a 2kW heater for 7h+ (final SOC about 10% judging by the amount of energy used - it was showing 3.14V under load, but recovered to 3.2V which was my goal to avoid any swelling when I remove the compression fixture)

- then I removed the busbars and I disassembled the battery.

This is only 3mm mild steel plate and ~204mm (8in) between bolts. It doesn't take "a crazy amount of pressure" to bow the middle out by about a mm, maybe 1.5mm tops.

In fact I was curious how much force does it take. I have an app on my phone called beam design (for when I DIY various metal things) and according to it this amount of bow is pretty much 300kg. So it seems I've hit the mark without even knowing :-D

View attachment 209405

But seriously, I was concerned about all of that force beeing concentrated on the edges too. No doubt the insulation sheet protected it as after I removed the fixture I can't see any damage to the casing. Not even an imprint in plastic. For the permanent version I'll weld supports onto this plate so there is no flex and I've ordered disc washers for the bolts. The fact this plate flexed is probably good as it avoided applying too much force.

After some thinking I decided the battery doesn't really need insulation as it will be in a basement where I never had the temperature go below zero (it's around 5C all year), but I'll add heaters just in case.

It definitely would be my preference, but all I could get without ordering in advance was 20,30,40 mm in 2mm thickness (under 1/8in thickness, about 3/4'',1in,1.5in) then there was this 50x3mm (2in x 1/8) bar that would leave me ~6mm clearance (1/4) so not much if a washer is dropped. But I was extra careful and it is dismantled by now.

I can do sketchy for a short time and not regret it... I'd not leave it like this.

Edit: I have an extra bit of info someone might find interesting:

Initially (after the battery was charged, but before bus bars were removed) the plate flex was almost inperceptible. I mean I looked at it and I wondered, is this plate flexing? It looks like it does a bit, but I'm not sure. I wish I used feeler gauge to measure, but I didn't. It certainly was a tiny flex. Then I removed the busbars to do the parallell arangement and only then the plate flexed by 1mm (maybe up to 1.5mm as said before, but most likely between 1 and 1.5). This means that just the busbars with screws torqued with a torque wrench to 6Nm were holding the batteries.

This makes me think, if you put your busbars on when batteries are discharged, torque them, then charge, you may actuallybe applying "compression" to all but the end cells without even knowing.

Also, the batteries did shrunk again, after I discharged them back to (recovered) 3.2V. I believe it is not ideal to store them too long at such low SOC (10%) but I wanted to ensure they go back to the same size and it is hopefully only for a week or two at most.

I'll definitely prevent this for the next use of the fixture.Cool little app for the bending beam force calculator.

Glad to know it was just temporary. Knowing the surface area of the edges is so small nothing good could have come keeping that much pressure on such a small area compared to the rest of the cells.

No it was higher, no doubt due to my previous un-equalisation effort. During the most of the string charge it fluctuated around 20~60mV as the BMS was actively balancing. The balance current was pegged at 2A/-2A and the high and low cells would change frequently, but I got an impression the first and the last in the string were higher more often.When you did charge the full 48v assembled battery bank until a cell bit 3.51v how big a delta was there in cell voltages?

Was the delta <0.010v?

I personally used a scale to judge the force on the screws, then repeated that amount of torque.

If you don’t want to go by manufacturer specifications. What else should we short cut on?Reading some of the above, people like to play with their cells and go through a lot of effort.

At a minimum all you need to do is:

Get some shelving, probably wooden

Take the cells out of the shipping boxes and put the cells on the shelves positive to negative.

Attach cell compression using steel rods (maybe 1/4 inch, I forget exactly)

Attach bus bars

Attach BMS

Attach active balancer (you can get really high amp ones now like the nee)

Attach to the inverter

Turn on and use system

Double-check everything, check resistance of all connections, functionality of BMS/ balancer. Voltage settings etc.

Good to go.

Nothing else is really required.

Two strings in parallel is safe without issues. Three is pushing it. With more you need fuses in case of failure. I suggest doing the cells in parallel, then you can save money on the BMS and balancers.

IMO the easiest way is disc springs and threadlocker. There are online calculators you can put your disc spring dimensions in and how much you compress it. This gives you the force. For example I know when my disc springs arrive (1in diameter, 0.5in bore, 0.05in thick) I need to compress 20%. Then you threadlock so the nuts don't back out.How do you know you aren’t over compressing the cells?

Indeed, it's a hobby for many people. However, although it is my hobby I'm trying to meet the manufacturers spec so I can reliably tell 5/10 years down the line "have these been good cells"? Also if they fail there is no excuse that it is my fault.Reading some of the above, people like to play with their cells and go through a lot of effort.