I received 4x 280ah eve cells and am using the overkillsolar 120a 4s bms. I have the bms paramaters set to cut off at a per cell voltage of 3.65 and pack voltage of 14.6.

I received all my cells awhile back but had some supply issues getting the bms, so I waited almost 2 months before beginning the initial charge to top balance everything. I hooked everything up in series with the bms and it started charging the battery as a pack. My plan was to charge until the first cell hit 3.65 (cutoff by bms), then rewire in parallel to do the top balance.

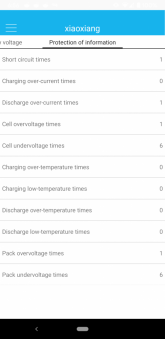

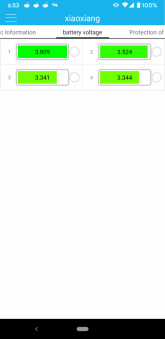

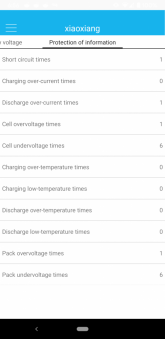

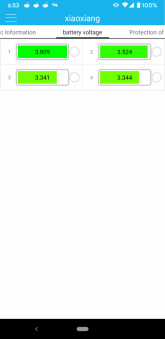

Well the cells i had were a lower SOC then I expected so it took a long time to charge it up initially. Last night i was asleep when the bms cutoff, but my partner (who knows next to nothing about batteries, etc) knew to disconnect the charger and did so. Now this morning I looked at the bms info and I see that battery #1 in my pack was charged up to 3.809! And this was after 8 hours of the battery resting without charge!

I unhooked the battery and now have them in parallel. The battery itself was not bulging and looked ok as far as I could tell. Is this battery still safe to use? How do I proceed from here? And why did the overkill bms not prevent this from happening?

I received all my cells awhile back but had some supply issues getting the bms, so I waited almost 2 months before beginning the initial charge to top balance everything. I hooked everything up in series with the bms and it started charging the battery as a pack. My plan was to charge until the first cell hit 3.65 (cutoff by bms), then rewire in parallel to do the top balance.

Well the cells i had were a lower SOC then I expected so it took a long time to charge it up initially. Last night i was asleep when the bms cutoff, but my partner (who knows next to nothing about batteries, etc) knew to disconnect the charger and did so. Now this morning I looked at the bms info and I see that battery #1 in my pack was charged up to 3.809! And this was after 8 hours of the battery resting without charge!

I unhooked the battery and now have them in parallel. The battery itself was not bulging and looked ok as far as I could tell. Is this battery still safe to use? How do I proceed from here? And why did the overkill bms not prevent this from happening?