lukassteiner

New Member

- Joined

- Jan 3, 2022

- Messages

- 4

I have a 48v DIY Lifepo4 battery with 16 cells and a Daly BMS.

Before I used it, I top balanced it and it worked well for about a year.

Recently, I noticed that the BMS cut the load very quickly.

I was able to charge the battery fully again but then when I connected the load, the BMS cut it again.

Now, I disconnected the separate cells and measured their voltage.

Every cell has a voltage of 3.3v except for one that has 1.1V.

I charged this one cell manually with a DC power supply for a minute. When I measured it again, that cell was 3.0V.

What would you guys recommend to do?

What I though of doing:

Test the load of this one cell. I just don't know how.

Or replace this cell and top load all the cells again.

Or assemble the battery again and connect it to my inverter to test the load again with 48v.

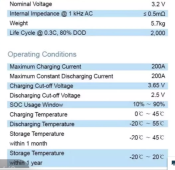

attached are the specifications of my battery cells

Before I used it, I top balanced it and it worked well for about a year.

Recently, I noticed that the BMS cut the load very quickly.

I was able to charge the battery fully again but then when I connected the load, the BMS cut it again.

Now, I disconnected the separate cells and measured their voltage.

Every cell has a voltage of 3.3v except for one that has 1.1V.

I charged this one cell manually with a DC power supply for a minute. When I measured it again, that cell was 3.0V.

What would you guys recommend to do?

What I though of doing:

Test the load of this one cell. I just don't know how.

Or replace this cell and top load all the cells again.

Or assemble the battery again and connect it to my inverter to test the load again with 48v.

attached are the specifications of my battery cells