Hello guys!

I am using my 16S2P bank made of 32x CATLs of 302Ah with a Seplos BMS for a few months now, and so far so good. I am prospecting however to build a second bank of 16S2P, but I would kinda go with EVEs 304Ah this time. It looks like it is easier to get grade A cells from EVE than CATL these days... Mine were bought from Docan, I don't say that they are bad, but some were slightly bloated... Now, in day to day usage, being compressed, actively balanced, they act quite well in terms of capacity and balance.

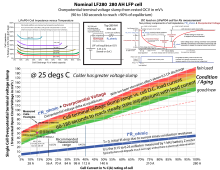

So - my question for you, based on your experience, should it be OK to mix 1 bank of CATLs and 1 bank of EVEs of almost the same capacity? My invertor is an Deye 12K 3P, so charge and discharge is on low rates even on my current setup. Adding a second bank would make charge and discharge at half for each bank - so stress will be at minimum. But, being different vendors, the batteries would have a slightly different charge/discharge curves - I don't know how much would this impact me.

Thanks!

I am using my 16S2P bank made of 32x CATLs of 302Ah with a Seplos BMS for a few months now, and so far so good. I am prospecting however to build a second bank of 16S2P, but I would kinda go with EVEs 304Ah this time. It looks like it is easier to get grade A cells from EVE than CATL these days... Mine were bought from Docan, I don't say that they are bad, but some were slightly bloated... Now, in day to day usage, being compressed, actively balanced, they act quite well in terms of capacity and balance.

So - my question for you, based on your experience, should it be OK to mix 1 bank of CATLs and 1 bank of EVEs of almost the same capacity? My invertor is an Deye 12K 3P, so charge and discharge is on low rates even on my current setup. Adding a second bank would make charge and discharge at half for each bank - so stress will be at minimum. But, being different vendors, the batteries would have a slightly different charge/discharge curves - I don't know how much would this impact me.

Thanks!