Shade is sometimes unavoidable, especially for mobile and marine systems. I'm hoping that this thread can serve as both a resource and a place for conversation on ways to minimize losses due to shading.

I am far from the most informed on the topic, but I've learned a thing or two:

I am far from the most informed on the topic, but I've learned a thing or two:

- Avoid Shade where possible. This is obvious but can't be understated, every other point is just mitigation, avoiding shade is always the best solution where possible.

- Use parallel wiring or a sensible combination of series and parallel wiring so losses stay localized to only the shaded panel.

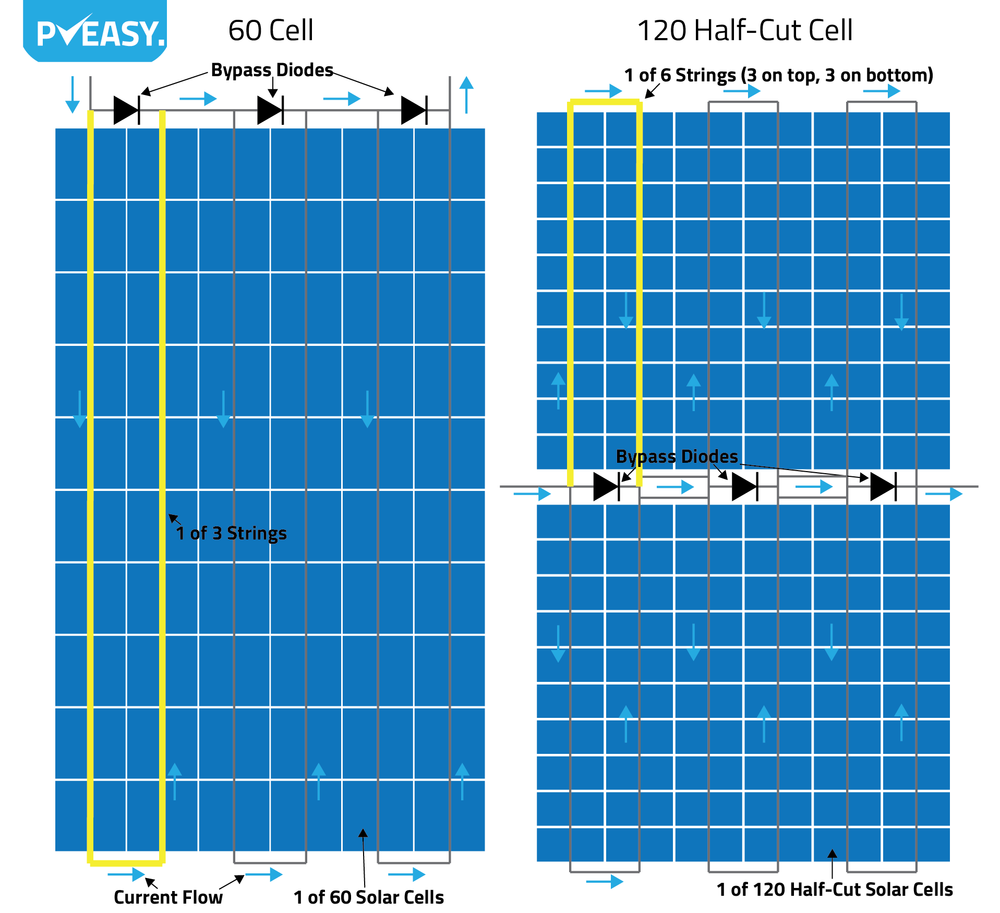

- Use panels that make good use of Bypass Diodes to minimize losses and reduce heat buildup

- Use multiple smaller MPPT controllers so that each panel's (or each group of panels') maximum power point is calculated independently

- Low 'reverse bias voltage' panels

- Solar Optimizers Similar in concept to using multiple MPPT controllers, solar optimizer allow per panel maximum power point optimization

- Microinverters I believe these have the same benefits as Solar Optimizers (per panel maximum power point optimization), as well as converting the DC output of the panel into AC.

Last edited: