Chris30559

New Member

- Joined

- Jun 20, 2021

- Messages

- 28

Hi Everyone,

So I've read a few threads about this already, but most seem to just ignore it since they are grid tied, and the power company doesn't care. My Setup is off Grid, So I am my own power company and waisted power is not ideal.

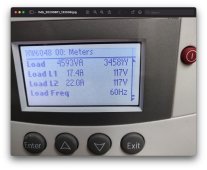

So anyway, I am running 2 well pumps with my XW6048 inverter. I noticed that I was drawing much more current from my solar/batteries than I expected. So I looked at my inverter meters and found that my apparent power "VA" is 4593 va, while my real power is 3458 watts. That works out to a Power Factor of 0.75. I run these pumps for a couple of hours each day, so this waist in power is significant. Is there anything that can be done to "fix" this, or at least improve it.

Thanks,

Chris

So I've read a few threads about this already, but most seem to just ignore it since they are grid tied, and the power company doesn't care. My Setup is off Grid, So I am my own power company and waisted power is not ideal.

So anyway, I am running 2 well pumps with my XW6048 inverter. I noticed that I was drawing much more current from my solar/batteries than I expected. So I looked at my inverter meters and found that my apparent power "VA" is 4593 va, while my real power is 3458 watts. That works out to a Power Factor of 0.75. I run these pumps for a couple of hours each day, so this waist in power is significant. Is there anything that can be done to "fix" this, or at least improve it.

Thanks,

Chris