ThrottleAbuse

New Member

- Joined

- Aug 18, 2022

- Messages

- 22

Hello, I am currently in the process of planning and upgrading my RV power system.

I am replacing my 4 worthless 6v 230Ah batteries with 2 Epoch 300Ah V2 lithiums. To do so I need to add a DC to DC charger and I want to be able to charge the lithiums as quickly as possible when driving my RV or running my generator.

I also plan on adding some additional solar which I would like some help picking the specs and components. I have purchased a Renogy IP67 50 DC to DC MPPT charger. I will be using the 50A Renogy as the controller for it so that unit will handle DC to DC and the added solar. Right now I was thinking three 200W 24V panels and one 100W 24V panel all wired parallel. I had seen some on Richsolar that would work but now I cant find the 100W 24V panels. I dont have any preference here I just want to maximize the controllers capacity. The controller is rated for 720W so this should max out the controller. I have lost of room on the roof. 6 or 7 panels will easily fit. Renogy recommends a 60A and 70A fuse on the output and input sides.

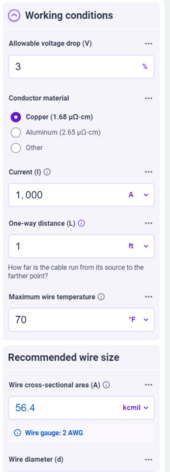

I also plan on adding a Recpro 125A AC to DC charger to boost charging capacity while on shore power or while running the generator. I will wire this to an open breaker on the current 120V system that only runs on shore or generator power. I am not particularly attached to the Recpro but this seems like a pretty basic use case so it doesnt seem like I need something expensive. I believe I will be able to mount it close enough to run 4awg wire. I may need to increase that to 2awg. Is a ANL 175A fuse safe here?

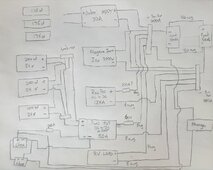

Here is a drawing of what I have planned. The Jaboni solar system is already installed and I am not 100% sure on how its connected but by knowing the specs I think all three 175W panels are wired in parallel. I also already have a Magnum 3000W inverter thats already installed. I will be disabling the auto merge and leaving a manual option to join house and chassis batteries.

For the battery install I see people recommending MBRF fuses. Do I just need a 600Ah fuse on the bus bar side since each batteries BMS is rated for 300A max draw? Do I need any other fuses on the battery part of this upgrade? 4/0 awg wire should be ok here between batteries and to the bus bars. Distances will be short.

Any advice on any part of this upgrade is much appreciated.

I am replacing my 4 worthless 6v 230Ah batteries with 2 Epoch 300Ah V2 lithiums. To do so I need to add a DC to DC charger and I want to be able to charge the lithiums as quickly as possible when driving my RV or running my generator.

I also plan on adding some additional solar which I would like some help picking the specs and components. I have purchased a Renogy IP67 50 DC to DC MPPT charger. I will be using the 50A Renogy as the controller for it so that unit will handle DC to DC and the added solar. Right now I was thinking three 200W 24V panels and one 100W 24V panel all wired parallel. I had seen some on Richsolar that would work but now I cant find the 100W 24V panels. I dont have any preference here I just want to maximize the controllers capacity. The controller is rated for 720W so this should max out the controller. I have lost of room on the roof. 6 or 7 panels will easily fit. Renogy recommends a 60A and 70A fuse on the output and input sides.

I also plan on adding a Recpro 125A AC to DC charger to boost charging capacity while on shore power or while running the generator. I will wire this to an open breaker on the current 120V system that only runs on shore or generator power. I am not particularly attached to the Recpro but this seems like a pretty basic use case so it doesnt seem like I need something expensive. I believe I will be able to mount it close enough to run 4awg wire. I may need to increase that to 2awg. Is a ANL 175A fuse safe here?

Here is a drawing of what I have planned. The Jaboni solar system is already installed and I am not 100% sure on how its connected but by knowing the specs I think all three 175W panels are wired in parallel. I also already have a Magnum 3000W inverter thats already installed. I will be disabling the auto merge and leaving a manual option to join house and chassis batteries.

For the battery install I see people recommending MBRF fuses. Do I just need a 600Ah fuse on the bus bar side since each batteries BMS is rated for 300A max draw? Do I need any other fuses on the battery part of this upgrade? 4/0 awg wire should be ok here between batteries and to the bus bars. Distances will be short.

Any advice on any part of this upgrade is much appreciated.

Attachments

Last edited: