SlimyLemur56

New Member

- Joined

- Feb 20, 2020

- Messages

- 27

I have 4x 3.2v 105AH cells, and I will be pulling a small amount of current from them (generally <5A@12v with a 15A breaker). The studs are M8, that I had to put in myself after the M4 terminals stripped out immediately when I got them. The battery will be compressed in a pelican case I have built out with padding on the inside, as part of a travel kit.

To paint a picture of the lifestyle it will live: it will sit on the concrete in my garage unused, and then a few times a month, get picked up, put in the car, taken out to a field, set on the earth over night, back in the car to the garage. So it will not be subject to ongoing vibration, but occasional weight-shifting transport within it's padded home. It will be moved carefully by me, so not post-office-banged-around, just regular I-tried-not-to-bang-it-around-banged-around.

Because of the low amount of amperage I will be pulling from it (with a breaker also), and to reduce the chance of weird stresses put on the terminals when the weight shifts, in lieu of traditional bus bars I am using flexible, short, double-runs of 12awg wire between the cells.

Now that I have my studs glued in (https://diysolarforum.com/threads/cleaning-the-terminals-after-jb-welding-studs-in.48723/) I have some final question about nuts, lock washers, and torque.

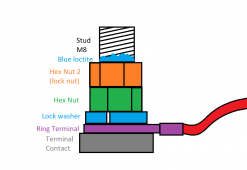

My plan is to put the ring terminals on, then put on lock washers like these

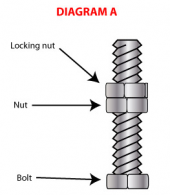

Then put an M8 hex nut on. Tighten it enough to flatten the lock washer. Then put another hex nut on as a lock nut over the first to lock it like this

And usr blue loctite on the locking nut for extra security.

Does this seem sane?

If I am using this type of springy lock washer, is it good enough to tighten the nut down until the washer is flat, or do I need to be concerned about precise numerical torque?

To paint a picture of the lifestyle it will live: it will sit on the concrete in my garage unused, and then a few times a month, get picked up, put in the car, taken out to a field, set on the earth over night, back in the car to the garage. So it will not be subject to ongoing vibration, but occasional weight-shifting transport within it's padded home. It will be moved carefully by me, so not post-office-banged-around, just regular I-tried-not-to-bang-it-around-banged-around.

Because of the low amount of amperage I will be pulling from it (with a breaker also), and to reduce the chance of weird stresses put on the terminals when the weight shifts, in lieu of traditional bus bars I am using flexible, short, double-runs of 12awg wire between the cells.

Now that I have my studs glued in (https://diysolarforum.com/threads/cleaning-the-terminals-after-jb-welding-studs-in.48723/) I have some final question about nuts, lock washers, and torque.

My plan is to put the ring terminals on, then put on lock washers like these

Then put an M8 hex nut on. Tighten it enough to flatten the lock washer. Then put another hex nut on as a lock nut over the first to lock it like this

And usr blue loctite on the locking nut for extra security.

Does this seem sane?

If I am using this type of springy lock washer, is it good enough to tighten the nut down until the washer is flat, or do I need to be concerned about precise numerical torque?