Hi,

I'm upgrading my solar system after about 8 months since I built it with one extra lithium battery that I will wire in parallel with the older one. The battery is Elkersolutions lifepo4 24v 100Ah. Currently I have one 300A MRBF fuse right on the positive terminal.

What I researched so far is that it's recommended to fuse each lithium battery when connecting in parallel. But they were usually talking about systems that have 4 or more batteries connected in parallel. My system is rather small, so I'm trying to find out if it is that dangerous to not buy one extra fuse and only use the main MRBF fuse on one battery terminal as I have been using so far. It's not really about me not wanting to spend extra money on an additional fuse but the problem is, it takes 2 weeks at least to ship that fuse to my place and we're currently in the process of building a small house so we use a lot of tools and we kind of need that battery working as soon as possible. So I need to know if it's okay to wire it without a fuse at least for now.

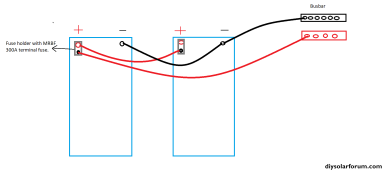

I will just explain my thinking here, so please correct me if I'm wrong. The reason why there need to be a fuse between each battery is that in case there is a dead short in one of them, the wire connecting them can get hot and catch on fire. Is this the only reason why I should have a fuse in between those 2 batteries? And if I understand correctly, it all depends on how much I trust the BMS in this battery, because the BMS should take care of this problem unless it fails for some reason. But isn't the BMS built specifically for taking care of this situation? And in case I really need to fuse it, would the same 300A MRBF fuse be suitable? I will attach a drawing of how I would fuse it. The cables used are 2/0 AWG or in my case 70mm2.

Thanks

Jan

I'm upgrading my solar system after about 8 months since I built it with one extra lithium battery that I will wire in parallel with the older one. The battery is Elkersolutions lifepo4 24v 100Ah. Currently I have one 300A MRBF fuse right on the positive terminal.

What I researched so far is that it's recommended to fuse each lithium battery when connecting in parallel. But they were usually talking about systems that have 4 or more batteries connected in parallel. My system is rather small, so I'm trying to find out if it is that dangerous to not buy one extra fuse and only use the main MRBF fuse on one battery terminal as I have been using so far. It's not really about me not wanting to spend extra money on an additional fuse but the problem is, it takes 2 weeks at least to ship that fuse to my place and we're currently in the process of building a small house so we use a lot of tools and we kind of need that battery working as soon as possible. So I need to know if it's okay to wire it without a fuse at least for now.

I will just explain my thinking here, so please correct me if I'm wrong. The reason why there need to be a fuse between each battery is that in case there is a dead short in one of them, the wire connecting them can get hot and catch on fire. Is this the only reason why I should have a fuse in between those 2 batteries? And if I understand correctly, it all depends on how much I trust the BMS in this battery, because the BMS should take care of this problem unless it fails for some reason. But isn't the BMS built specifically for taking care of this situation? And in case I really need to fuse it, would the same 300A MRBF fuse be suitable? I will attach a drawing of how I would fuse it. The cables used are 2/0 AWG or in my case 70mm2.

Thanks

Jan