That’s one of the things I’m trying to figure out with my posts -what should the voltage measurement be across a battery with a BMS that has “disconnected”?

I assumed it would read 0, but I’m finding info online that suggests some could read as high as +6/7 Volts, and regardless of what it reads, some have suggested it shouldn’t be trusted and the value is just arbitrary.

Remember once I put a load on the battery that has that low resting Voltage of +13.18 it will drop down to +6.5V or so, but strangely it will continue to let me pull power from it with an 12V LED dome light.

Strange indeed.

Regarding the cases, they are quite a bit nicer than most I have seen in videos of tear downs, very similar to the Valence XP except the boards aren’t separately accessible, but I think I can get into it without too much carnage. Hoping they used a butyl tape instead of glue.

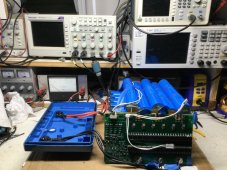

I have been in contact with the manufacturer. I bought them direct and had them built to order with the BMS configured for high discharge rates.

I let them know the first time this happened some months ago, and contacted them last week to let them know it has happened again, and asked some specific info about the BMS and how it should behave, Waiting to hear back now.

I think I am approaching my Warranty, but you know living in Hawaii we are kind of on our own, so I may have to see if I could at least get a replacement BMS if in the end I suspect it to be at fault.

Hoping if/when I get it opened up I can identify the brand of BMS, and with any luck there might be a Bluetooth module already built in that I can try to communicate with. Other buyers of EWT have opened them up and discovered a full featured BMS.

I wouldn’t be surprised if in the end I find a fried Gecko or a colony of those pesky red ants inside ?