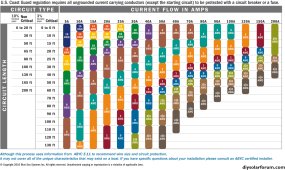

This chart also confuses me.

1) Circuit length generally means up and back, so distance is half of what they are stating?

2) Most homes are wired with 14 AWG for 15 amp circuit, 12 AWG for 20 amp circuits, and 10 AWG for 30 amps circuits, but the chart shows those gauges only valid for 20 feet at a 10% loss. Few homes, especially multi-story ones, have circuits that short (maybe 10 feet if 1) holds).

2A) Of course homes are wired with breakers rated at the same amperage of the above (e.g. 20 amp breaker fed by 12 AWG wire), and those breakers are rated at 80% continuous load, but that 20% delta evaporates pretty quickly on that chart as one bumps the distance.

2B) I've had some advice that NEC requires the wires to be 25% greater gauge to expected amperage. So if expected is 16amp, plan for 20amps. Feels like that is double counting if you equate "expected" to "peak", but lines up completely with "expected" = "continuous".

3) Worst reading I can think of: Want to carry 30 amps peek/24 amps continuous for 100 feet (200 foot "circuit") would require #2 copper wire?!?!

Clarification, along with concern every house I've even seen the wiring in is seriously off (and I've owned a number of rental homes so have seen a lot) please. Ex: a 50x30 home with an electrical panel in the garage (far corner) mostly wired up with 14 AWG shy a single 10AWG for a dryer.

Brain is frying when I think of 100 ft extension cords with the same gauges as my home wiring example.