chaosnature

New Member

- Joined

- Sep 15, 2022

- Messages

- 527

i assume you have different cable lenth or diameter from inverter to your battery or your batteries have very different internal resistance.

The inverter charges both batteries but one takes much more A than the other.

after you stop charging, that one gets discharged and charges the other battery.

This is not good and will cause big problems where one runs into OVP and the other does not. I bet you will destroy one or both BMS over time.

But without any detailed scematic how you physically connected your batteries like pages before mentioned, we cannot help you

Many of your problems could be related to that issue - you need to sort that out and fix that!

Many of your problems could be related to that issue - you need to sort that out and fix that!

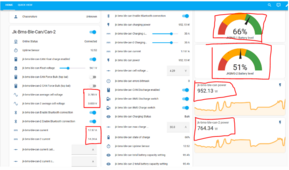

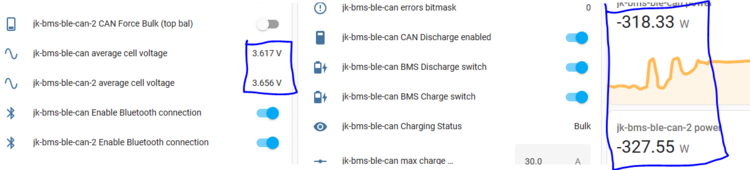

As it stands right now - i have no more issues while using the User-Defined settings - my battery cable length and gauge are approximately the same.... as i said earlier, i have fixed the wiring...spent all last night fixing it...if there was issues with the wiring i would know.

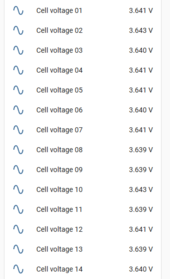

The average voltage from each other looks pretty close for a system that dont talk to each other so i am comfortable that there is no danger

the system behaves normal and near perfect

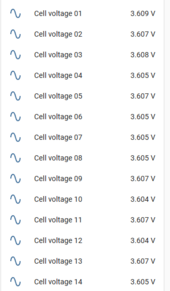

I also keep a close eye on the individual cells across both batteries and they are pretty much the same - so again no problems

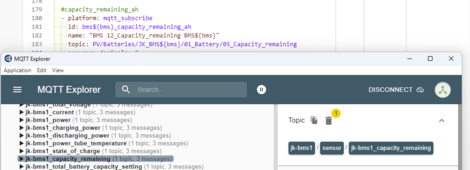

the issue which was the last of my issues was to do with the Pylon protection settings which is not available (for edit) to the ordinary personnel - only if one has an API to edit the values I suppose

That is my conclusion based on the comparison of the values between the User-Define and the Pylon available editable parameters.