Hogheavenfarm

Regulation Stifles Innovation

- Joined

- Jun 24, 2022

- Messages

- 443

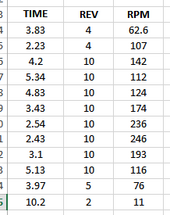

During the wind last night, the volts did not increase at all, was still reading battery voltage (13.1), (its on the video) if I remember correctly. Easier for me to use my clamp meter at the inside feeds, as it is usually during heavy rain or heavy snow that the turbine is spinning up nicely, and standing outside in the dark in the rain trying to read a clamp meter is not any fun at all. Currently the voltage meter is connected across the positive and negative feeds, since they connect directly to the battery they read battery voltage, my thought was it would show increased voltage when it spun up to over battery voltage, but I did not see that, so either the resistance is too high (not allowing the voltage through), or the turbine has stopped producing power (damn sparrows!). Will disconnect the feeds and see if I can spin by hand to verify power output.

I didnt mean disconnecting the leads and leaving them, I meant disconnecting and placing the DMM between them, as you indicated "in series with", so I was brainstorming that and how to safely connect and disconnect while power is being applied. I wasn't clear, sorry.

I didnt mean disconnecting the leads and leaving them, I meant disconnecting and placing the DMM between them, as you indicated "in series with", so I was brainstorming that and how to safely connect and disconnect while power is being applied. I wasn't clear, sorry.