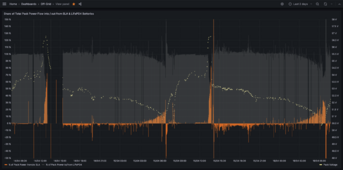

Exactly. This is my PV output power (and load) curve for a typical day of my off-grid system. Pool pump mostly (and in this case also a pool cleaning robot for a couple of hours). There's so much unused capacity that efficiency losses in storage are not really a factor. Obviously the size of that Unrealised Capacity area varies with season and weather, even so, it is well above demand on all but the worst days.

The main exception is when the system is occasionally performing its primary task of household backup during grid outage.

View attachment 72275

The reason I'm interested in exploring the potential of adding some LFP is I could possibly run our general household circuits from this off-grid system and free up my grid-tied system (a bit) for other loads I plan to move onto it, hot water to begin with and later an EV.

But I do not want to cycle my lead acid storage much, hence having some LFP to look after most of the daily cycling, leaving the lead to be ballast and for grid outage backup.

Most of the household circuit separation is already done by the way I have our transfer switch wired to exclude high power draw circuits which I don't want to operate from backup supply (oven, induction stove, ducted aircon etc). They are only ever going to be grid connected. But I have one or two trickier circuits to solve before I can consider this option.

Just circling back to this thread for a bit of an update.

Since writing the above in November 2021, I did indeed add some LiFePO₄ to my SLA battery pack. I did that back in August 2022, adding 2 x 5 kW LiFePO₄ server rack batteries to my 20 kWh of sealed lead acid (8 x

Enersys Supersafe SBS190F 12 V batteries in two banks of four). I added a extra 5 kW LiFePO₄ server rack unit in May 2023.

The batteries have been in parallel operation ever since. This post shows the system:

Does your inverter have Volt-Var? I think that is supposed to let it backfeed power with less voltage rise. The current is driven a bit out of phase, I think.

diysolarforum.com

Each battery has its own OCPD (fuses for all, and the LiFePO₄ also have breakers). I have a battery voltage equaliser on each of the lead acid banks. The LiFePO₄ batteries use a PACE BMS with an on board balancer (but low current).

The basic operation is the LiFePO₄ does the daily cycling, while the SLA is maintained as reserve capacity for outages. In this way I limit discharge to ~15 kWh from a full charge, unless I need it (e.g. during grid outage). Else the hybrid battery pack voltage rarely falls below 50 V. It was always my expectation that the SLA would give the LiFePO₄ a "soft landing" once the voltages got low (for LiFePO₄). I rarely tap into the capacity of the SLA.

For monitoring I use a Victron Smart Shunt for the whole hybrid battery. In the early days I spent a fair bit of time doing manual monitoring with a DC clamp meter and the LiFePO₄ BMS displays just until I was satisfied the system would operate just fine.

With the Solar Assistant monitoring system I was able to also connect to the BMS of the server rack LiFePO₄ batteries however Solar Assistant has a limitation in that it is not (yet) able to monitor both the Victron Shunt data and the LiFePO₄ BMS data - I had to choose one or the other. While I did track the LiFePO₄ BMS data for a while I ultimately chose to prioritise tracking the Smart Shunt as that was providing the status of the whole hybrid battery and I have home, load and supplemental charging automations which use this data.

I would from time to time manually check the LiFePO₄ battery display panels. After a while I realised it was all working just fine in this configuration.

All the data is integrated with Home Assistant and captured via InfluxDB and can be charted with Grafana. This was nice but I still did not have monitoring to track how the individual chemistries were performing.

But now I do.

I had a spare Raspberry Pi mini computer and so added a second instance of Solar Assistant and have that exclusively monitoring the PACE BMS data from the LiFePO₄ batteries. It's also integrated with Home Assistant / InfluxDB / Grafana.

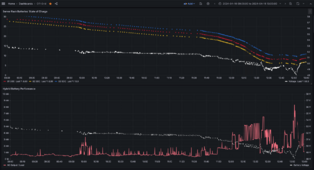

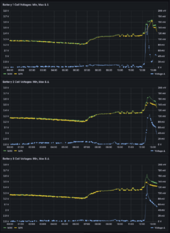

Usual stuff, combined data plus key stats from each battery. Things like min/max cell voltages and the cell voltage delta (this while I was doing some controlled charging to a higher voltage for recalibrating the BMS SOC values:

But because I am now capturing independent data from the LiFePO₄, I can compare that with the whole hybrid battery data and monitor the difference between them.

Measurement accuracy differences aside, it can at least provide some insight into the role the SLA plays during charge and discharge.

In essence, the Hybrid pack power flow minus the LiFePO₄ pack power flow = the SLA pack power flow. So I have set up some charts to monitor it.

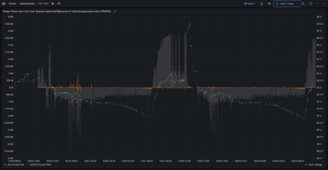

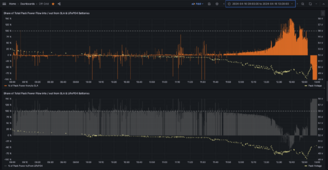

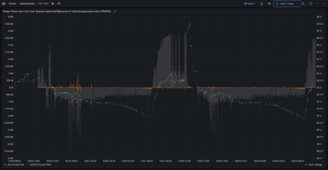

Here is a charting showing this, i.e. the SLA power flow. I have also put the pack voltage (dots) on the right axis:

Can see that during the last two days during discharge and charge the power flow to/from the SLA is not high.

Note the pack voltage range is between ~ 51 V and 57 V. I normally don't charge that high (56.4 V is my normal setting) but I was doing some BMS SOC recalibration yesterday.

The occasional spikes are likely data artefacts (aliasing) as the data sampling rate for each monitoring device is not exactly equal. They could be smoothed out with some filtering but for now I'm just posting the raw data.

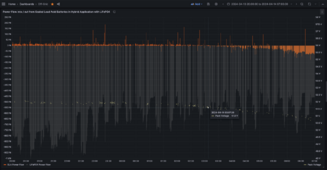

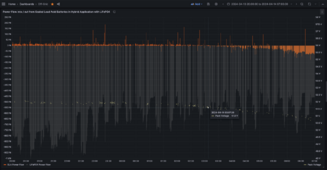

Now if I add the LiFePO₄ power flow to the chart we can see just how small that SLA power flow is relative to the LiFePO₄ charge and discharge contribution (note the power axis rescaled from +/- 500W to +/- 5kW):

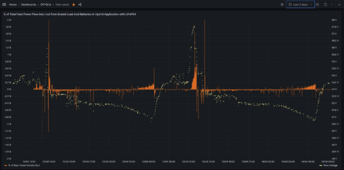

Zooming in on the period of discharge overnight, this showing from 8PM last night to 7AM this morning:

We can see that initially the SLA is taking a little power from the LiFePO₄. It is in effect a parasitic load. Not a big load (<20W), but it is taking some of the energy. However as voltage drops so does the parasitic load.

At around 3AM, when the pack voltage had dropped to about 51.6 V - 51.7 V the SLA power flow was neutralised and then it gradually started to reverse direction, with the SLA now beginning to contribute to the overall supply of loads. That contribution gradually increases the lower the pack voltage goes. It is a minor but growing contribution, and not long after that the sun came up and charging took over, with voltages rising again.

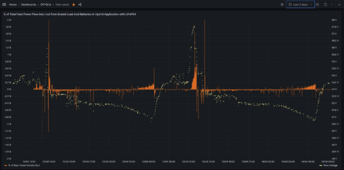

This is pretty much the same chart, except this one shows the SLA power as a percentage of the total hybrid pack power:

Can see that during my normal daily operation, the SLA is responsible for well under 1% of the total battery energy flow.

On Tuesday this week we have a planned grid outage for some power pole maintenance. Power is expected to be turned off sometime after 9AM and not be back on until early afternoon. So this provides a good opportunity to let the Hybrid pack voltage drop further and allow the SLA contribute much more energy than it normally would.

After the grid returns, it is likely we won't have enough solar PV power to recharge the full pack before the day is done, so I plan to use my electric car's vehicle to load facility to provide a supplemental charge source. It will be able to supply a steady source of charge so I can track how the batteries behave during recharge.

I will report back on how it goes.