eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

My Class A AGM batteries started to loose capacity especially when cold. So I got my self one of the newer group 24 LFPs.

Elefast 100ah with Bluetooth. My 12V system does only provide power to the lights, furnace etc. The 120V side is covered by a higher voltage solar system

Currently testing if this is really just a plug'n play install.

1. 120V dumb 35A converter - single voltage 13.8V

- check the LFP charges to about 80% and gets very slow.

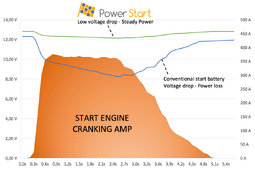

2. Start 5500W Onan Generator

No problem - pulls 110A for a few seconds generator starts faster then on Lead.

Todo:

3. 100W Panel PWM controller change to LFP, don't care too much about peak performance - just to keep it topped up when stored

4. Alternator Charging - 110A Alternator - which charges the house battery in parallel with the starter battery.

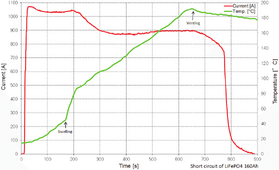

Since this battery is only 100AH - I don't think it should overheat the alternator. It is not a big bank, but lets measure.

Probably do a few tests:

Discharge to 80% - alternator charge current: Temperature:

Discharge to 50% - alternator charge current: Temperature:

Discharge to 30% - alternator charge current: Temperature:

Discharge to 10% - alternator charge current: Temperature:

Any other idea what I should test with that battery in an RV? My goal is to figure out what really needs to be changed over when switching to LFP or if this all just marketing and selling us extra stuff.

Last edited: