Only if lines are over 25 feet in length. Read the manuals, just about every single manual will state the unit is pre-charged for 25 feet or less of line.

I've lengthened line sets, shortened long line sets. It is in the manual how to compute if additional refrigerant is needed and how much.

i spent a lot of time in the manual for this unit, maybe i missed it, but there are no details on how much refrigerant to add or remove. The spec sheet does have an entry like .2oz per foot and then i purchased this book from AC service tech channel, Craig, he had some forumulas in there, that seemed like, well its just the way it works depending on length and pipe size, Craigs youtube and book had alot of useful information. Worth the $100 bucks or whatever his book cost.

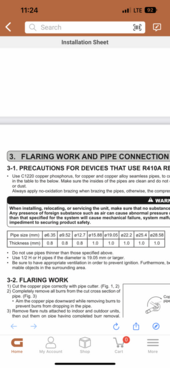

System Data Design Pressure [PSI Gauge (PSIG)] <651

Refrigerant R410A/45.86 oz.

Refrigerant Pre-charge 16.4 ft.

Additional charge per ft 0.2 oz.

Liquid valve 0.25 in. (6.35mm)

Gas valve 0.5 in. (12.7mm)

Max refrigerant pipe length 49 ft.

Max difference in level 26 ft.

I have 30lb can of Refrigerant i bought, was like $299 shipped. Have not had to use it, but hopefully it doesn't go bad or anything, i'll have to look that up actually.

My co-worker, we had a good month so i bought him one of these mini splits but the solar hybrid one. When he gets back in a few weeks we will put his in and he already bought a 50 ft line set. So we will use that refrigerant can then I'm sure. Pull another vaccum, and see what happens.

So my career as an amateur HVAC installation specialist is far form over