I'm failing to see the need for a battery quick disconnect personally, you can't really go wrong with a lug and bolt (carful with your washers folks) how much longer does it really take to undo a bolt. People might comment on torque but if you don't have a torque wrench just tighten it till your elbow clicks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beware of the APEXIUM BOX Connectors

- Thread starter GummiSolar

- Start date

wpns

Solar Joules are catch and release

I dunno, the Degson connectors on my EG4 PowerPro batteries really made things go together easier, and adding more or reconfiguring will be trivial as well.I'm failing to see the need for a battery quick disconnect personally, you can't really go wrong with a lug and bolt (carful with your washers folks) how much longer does it really take to undo a bolt. People might comment on torque but if you don't have a torque wrench just tighten it till your elbow clicks.

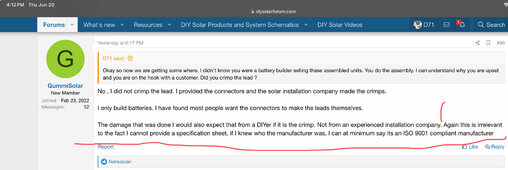

GummiSolar

New Member

- Joined

- Feb 23, 2022

- Messages

- 56

That certificate is for a 18650 battery cell, what is the relevance?View attachment 223250

View attachment 223251

Ddp Shipping 7.6kw Solar Energy System 25.6v 280ah 300ah 310ah 320ah 330ah Lifepo4 Storage Battery Pack Box 24v 280ah Diy Kit - Buy Apexium Customized 24v 48v 280ah Lifepo4 Battery Box 15kwh Apex 16s Ev 280ah 302ah Lifepo4 Akku Diy Case Only Empty Bo

Ddp Shipping 7.6kw Solar Energy System 25.6v 280ah 300ah 310ah 320ah 330ah Lifepo4 Storage Battery Pack Box 24v 280ah Diy Kit - Buy Apexium Customized 24v 48v 280ah Lifepo4 Battery Box 15kwh Apex 16s Ev 280ah 302ah Lifepo4 Akku Diy Case Only Empty Box 12v 24v 280ah Diy Battery Kit With 200a Jk...www.alibaba.com

Suijkerbuijk

I cannot be held responsible for this information.

Wat is the problem with a washers ?I'm failing to see the need for a battery quick disconnect personally, you can't really go wrong with a lug and bolt (carful with your washers folks) how much longer does it really take to undo a bolt. People might comment on torque but if you don't have a torque wrench just tighten it till your elbow clicks.

Can you explain this to me ?

I see it pop up in this topic

My self i do not use it .

But i do use a spring in it against coming lose.

Wat is the problem with a washers ?

People sometimes put a washer between the battery terminal and bus bar/lug. The bus bar (or lug) should be in direct contact with the terminal. A washer can then be placed on top of the bus bar/lug before the nut.

Someone slightly melted a battery cable and fuse holder recently here by adding a washer between contact surfaces, washers/spring washers are fine just don't turn them into fusible linksWat is the problem with a washers ?

Can you explain this to me ?

I see it pop up in this topic

My self i do not use it .

But i do use a spring in it against coming lose.

You must of missed the part that some ppl that do that are still “unconvinced” in another post. Btw I don’t drink alcohol either.People sometimes put a washer between the battery terminal and bus bar/lug. The bus bar (or lug) should be in direct contact with the terminal. A washer can then be placed on top of the bus bar/lug before the nut.

Only documents seen on your empty battery box as advertised at Alibaba.That certificate is for a 18650 battery cell, what is the relevance?

I read you are in Austria in another post about these batteries and your reported same burned up connector problem.

As a manufacturer you best hope charges are not pressed. That looks bad.

In USA most DIY is fine for yourself but can’t do it for profit-hire and in some cases can’t do it for other ppl even if for free. .

I tell many people "that's not going to work" and they still need to find out for themselves it's some form of primal learning instinct. Also you can't blame alcohol for making stupid decisions I haven't drunk a drop in almost 7 years and I still make terrible decisions regularly.You must of missed the part that some ppl that do that are still “unconvinced” in another post. Btw I don’t drink alcohol either.

I used to make desk lamps/standing lamps from junk and the liability in those was insane, I dread to think how bad it is for people trying to make cash from high amperage potential bombs in their spare time.

robbob2112

Doing more research, mosty harmless

Someone slightly melted a battery cable and fuse holder recently here by adding a washer between contact surfaces, washers/spring washers are fine just don't turn them into fusible links

The key point of that thread is the person used a stainless steel washer in the path of the current flow. Current flows from the battery pad to the lug face, not throught the threaded part.

In his case he had washer - fuse - washer - lug - washer - nut ... all stainless steel which will get hot because it isn't a good conductor.

So long as it isn't in the path of current flow you can use a steel washer as a spacer. If it is in the path of current flow you can use a pure copper washer that has been cleaned at it will act as a bus bar.

Personally I wouldn't even use a copper washer unless all the surfaces were copper especially on something I'm supposed to kinda do once and forget(might be an incoming idiot moment) surely galvanic corrosion would start to be an issue if the contacts were zinc plated or worse steel if your buying cheap lugs.So long as it isn't in the path of current flow you can use a steel washer as a spacer. If it is in the path of current flow you can use a pure copper washer that has been cleaned at it will act as a bus bar.

robbob2112

Doing more research, mosty harmless

Personally I wouldn't even use a copper washer unless all the surfaces were copper especially on something I'm supposed to kinda do once and forget(might be an incoming idiot moment) surely galvanic corrosion would start to be an issue if the contacts were zinc plated or worse steel if your buying cheap lugs.

I hear you.... where I have used copper washers is on top of MRBF fuses where the lug won't sit flat. i.e. what is needed is an extra wide lug. The extra wide lugs do exist but they aren't something I keep many of on-hand.

So, tinned copper top of the MRBF, copper washer, tinned copper lug - all using no-ox-id on the mating surfaces.

The no-ox-id would take care of the galvanic corrosion I think, probably not 100% but best you can do.

Post in thread 'Beware of the APEXIUM BOX'

https://diysolarforum.com/threads/beware-of-the-apexium-box.85763/post-1122391

robbob2112

Doing more research, mosty harmless

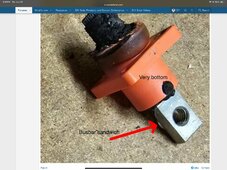

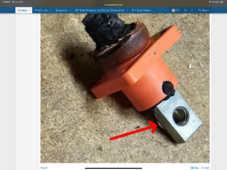

View attachment 223397

View attachment 223395

Post in thread 'Beware of the APEXIUM BOX'

https://diysolarforum.com/threads/beware-of-the-apexium-box.85763/post-1122391

We have seen the pictures, I am not sure what you are getting at?

What are your thoughts on those pictures. Like going to art museum some ppl view the art differently. Dominos fall in certain stacked start stop orders too. Rules apply. Some ppl think electricity is opinion. Some think it is feel good or feel bad…..feelings.We have seen the pictures, I am not sure what you are getting at?

What do you see in that photographic art?

Rorschach Test

robbob2112

Doing more research, mosty harmless

I see a very bad connection that caused very high heat. That heat spread both ways. If I had to guess comparing the burned and non-burned connector the cable end was not fully on at the time of the fault, but it could be the fault caused it to back off.

Not sure what you are pointing at in the bottom picture?

Not sure what you are pointing at in the bottom picture?

wpns

Solar Joules are catch and release

It feels like he’s trying to point out that there’s a washer welded to the post, but he won’t come right out and say it. If there is indeed a washer there, and it was in between the post and the busbar, then that would indeed be an inappropriate place for a washer, and very well could have caused this failure.I see a very bad connection that caused very high heat. That heat spread both ways. If I had to guess comparing the burned and non-burned connector the cable end was not fully on at the time of the fault, but it could be the fault caused it to back off.

Not sure what you are pointing at in the bottom picture?

On the other tentacle, if you look at the rest of the pictures in that thread, it looks like that one connector was out of line, so maybe it wasn’t tight?

Also, first glance it certainly looks like the plug-on connector was the source of the overheating, and Occam‘s razor says it was probably not plugged on properly.

robbob2112

Doing more research, mosty harmless

It feels like he’s trying to point out that there’s a washer welded to the post, but he won’t come right out and say it. If there is indeed a washer there, and it was in between the post and the busbar, then that would indeed be an inappropriate place for a washer, and very well could have caused this failure.

Well, in the picture he is pointing at the bottom side, the bar it is bolted to was on the top side. i.e. not in the current path that I can tell.

If OP moderated their own post

The black burned dot would have been on the bottom when connected. Look at the posted pictures again. Critical. The non burn dot side was on the bottom of busbar in a sandwich.

Goes back to the test of what you see or don’t see. These pictures were pointed out by 42OhmsPA. …. The link again:

diysolarforum.com

diysolarforum.com

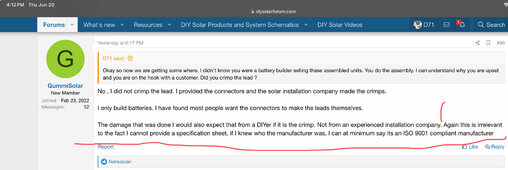

What you have here by OP is condemnation of a product….as 3rd hand. He is not giving first hand info. He is correct there is no certification to which he did not care until now.

rob you were provided with forum weblink to that picture. Did you not use it?Well, in the picture he is pointing at the bottom side, the bar it is bolted to was on the top side. i.e. not in the current path that I can tell.

The black burned dot would have been on the bottom when connected. Look at the posted pictures again. Critical. The non burn dot side was on the bottom of busbar in a sandwich.

Goes back to the test of what you see or don’t see. These pictures were pointed out by 42OhmsPA. …. The link again:

Beware of the APEXIUM BOX

Beware of the APEXIUM BOX this happened with the connectors they provided with the box. Also I talked to Apexium and they were very little help.

What you have here by OP is condemnation of a product….as 3rd hand. He is not giving first hand info. He is correct there is no certification to which he did not care until now.

robbob2112

Doing more research, mosty harmless

Apparently my visual/reading comprehension is severly lacking.... I claim lack of beer/caffine/glasses/zebras/owls/time machines/spatial orientation .... I see what you mean now

You are a gentleman and a scholarApparently my visual/reading comprehension is severly lacking.... I claim lack of beer/caffine/glasses/zebras/owls/time machines/spatial orientation .... I see what you mean now

I admit when am wrong and move on too. What we should do. Why don’t think good idea allow OP to moderate like here. He basically wants cya and stated as much. Did not care about crappy crimp problem either - “irrelevant” 2 bad problems meet in the middle.

devilljo

New Member

My factory-assembled Apexium 280A box with cables.

I suspect the mating between the plug and socket is electrically poor and not substantial enough for the loads it is meant to carry. At least in my unit it always felt like the plug connected to the socket easily with hardly any mechanical force required. My theory might be incorrect but I am not going to continue with these imitation connectors, I am replacing them with screw-down posts to which I can bolt down a ring lug.

These are not Futronics connectors. I bought Futronics from Minerals on AliExpress and although the Futronics does fit the socket they do not "click" in place and feel loose. They do not have any markings on them other than "200A 50mm".

I will rectify the busbar connecting the + terminals. As pointed out in another thread, it seems to have been incorrectly assembled and that could also have lead to heat in the cable - note the discoloured label.

I suspect the mating between the plug and socket is electrically poor and not substantial enough for the loads it is meant to carry. At least in my unit it always felt like the plug connected to the socket easily with hardly any mechanical force required. My theory might be incorrect but I am not going to continue with these imitation connectors, I am replacing them with screw-down posts to which I can bolt down a ring lug.

These are not Futronics connectors. I bought Futronics from Minerals on AliExpress and although the Futronics does fit the socket they do not "click" in place and feel loose. They do not have any markings on them other than "200A 50mm".

I will rectify the busbar connecting the + terminals. As pointed out in another thread, it seems to have been incorrectly assembled and that could also have lead to heat in the cable - note the discoloured label.

Attachments

Similar threads

- Replies

- 2

- Views

- 272

- Replies

- 33

- Views

- 613

- Replies

- 7

- Views

- 959