GummiSolar

New Member

- Joined

- Feb 23, 2022

- Messages

- 58

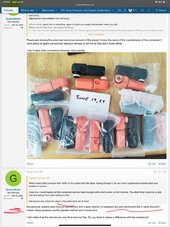

People are missing the point and Jenny just proved it. She doesn't know the name of the manufacturer of the connector! I have plenty of spare connectors! Apexium refuses to tell me or they don't know either.So for anyone else following along I emailed Jenny about potentially buying boxes and wanting replacement connectors in case I make a bad crimp...

Replacement are available, from US stock.

@GummiSolar good luck in rebuilding, again I'm glad you caught the problem when you did.

Please ask for help if you are unsure on things.

If I were you I'd order replacement connectors from Docan, get a proper crimper and make some new cables. While you're at it pick up and FLIR camera so you can check all your connections and components for excess heat. My UniT has saved my ass from potential disaster once so far.

I still firmly believe this in not an Apexium or Docan issue. I've never dealt with Apexium, I wouldn't hesitate to order from Docan again, 4 smooth transactions in the past couple years.

I apologize if I sound like an ass, it's not my intention, I get frustrated seeing repeat threads like this that place blame where it shouldn't be placed.

Last edited: