Yeah it looks like they did not insert it all the way. Bad installation as others have noted. You really need those ferrules to be inserted all the way in there unless this will happen every time.Good day to you all,

I have an EG4 18kPV inverter. It has been up and running for about 2 months and as far as I could tell there were no issues. System was designed by and purchased from Signature Solar (which were great to work with by the way).

I had the system installed by a local Solar company.

2 days ago, I noticed my solar production dropped by 25%. I opened the inverter door and the source of the problem was very apparent (see picture) - the 1st MTPP was fried.

the 10g PV wire was black/burnt too, going pretty far back on the wire itself.

MTPP #1A was the one that got cooked. #1B and #2 and #3 MTPP's were all working fine - hence the drop in 25% of my solar production.

my PV input array is as follows:

I have 36 Solorever 455W/49V panels. They are divided into four groups of 9 panels each (max wattage 4095 per grouping, 441V per grouping)

for the three MTPP inputs:

#1A (9 panels)

#1B (9 panels)

#2 (9 panels)

#3 (9 panels)

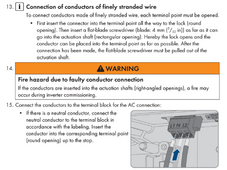

Has anyone ever seen this? Any ideas what could have caused this? Anyone every had to buy parts from SS/EG4 - as I will need to get new MTPP plug in ports.

I'm grateful for any input/suggestions/advice.

They do not look like proper ferrules or crimped with a ferrule tool either. All bad.