We havent had a copier/printer for several years at our place.

Got tired of the ink thing.

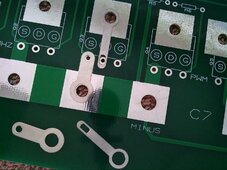

We need to get something now, but I would also like to try my luck with the photo transfer thing for making circuit boards.

Those of you that have done this method, what make and model of printer/copier am I looking for.

Thanks,

Randall

Got tired of the ink thing.

We need to get something now, but I would also like to try my luck with the photo transfer thing for making circuit boards.

Those of you that have done this method, what make and model of printer/copier am I looking for.

Thanks,

Randall