You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Busbar help for my bank

- Thread starter BretS

- Start date

That is a LOT of current capability...

Be sure you size the bussbar for the amp flow.

900amp would be 1C...

Be sure you size the bussbar for the amp flow.

900amp would be 1C...

BretS

New Member

- Joined

- Mar 30, 2021

- Messages

- 171

Am I wrong in thinking that the most the amp flow could be is the max my inverter could draw?That is a LOT of current capability...

Be sure you size the bussbar for the amp flow.

900amp would be 1C...

Am I wrong in thinking that the most the amp flow could be is the max my inverter could draw?

Safe assumption but size everything to handle the rating of the fuse. If you are using a 400A fuse make sure everything can handle that.

Also be cautious and plan how to limit potential for shorts between the cells, and between cells and the fuse. With 930Ah that is like a small Chernobyl if it shorts out and you can't stop it.

I would strongly suggest considering a fuse between the first 3P2S block and the second as well.

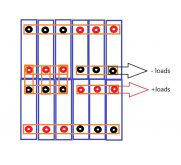

Putting together a 3P4S bank with twelve 310Ah cells and a REC active BMS. I could use some help with Busbars. Will it be ok to buy 1/4" x 1" copper and make my own? Will the longer, 6 terminal lengths be a problem? Thanks in advance!

View attachment 45307

Size the busbar for the current you want to draw. Bigger is always better, but as others have noted, make sure you have a fuse that will protect your wire. Usually your wire is what will limit current, both voltage drop and temperature rise.

Handy charts to correctly size 110 copper busbars. https://diysolarforum.com/resources/busbar-selection-table.104/

BretS

New Member

- Joined

- Mar 30, 2021

- Messages

- 171

Safe assumption but size everything to handle the rating of the fuse. If you are using a 400A fuse make sure everything can handle that.

Also be cautious and plan how to limit potential for shorts between the cells, and between cells and the fuse. With 930Ah that is like a small Chernobyl if it shorts out and you can't stop it.

I would strongly suggest considering a fuse between the first 3P2S block and the second as well.

Would a mega fuse between the two packs work?

I used 0.125" x 1.5" Copper Rectangle Bar for my single runs and 0.125" x 4" Copper Rectangle Bar for the 1S6P connections in the middle

The 1/8" is plenty thick enough to carry all the current you need and much easier to drill -- 1/4" copper grabs the bit a lot more

I have made Busbars with a drill press and with a handheld battery drill -- The handheld drill worked rather easy (surprisingly)

A machinist friend of mine showed me to put masking tape on the metal where I wanted to make my marks --then use a 1/8" bit just to make dimple in the metal --then drill the holes the size you need --- Slow is better and clamp your work down -- nothing worse than a spinning piece of bar stock

I use plenty of tape over all the terminals I'm not working on -- I had a mishap with my wedding band that taught me well ( millisecond short had my ring glowing and burnt a ring around my finger -- I decided to rotate my connections 90 degrees from your diagram -- therefore your pos and neg terminals are further apart -- this way you have two 3 hole busbars / two 3x3 square busbars / one 6 hole busbar

The 1/8" is plenty thick enough to carry all the current you need and much easier to drill -- 1/4" copper grabs the bit a lot more

I have made Busbars with a drill press and with a handheld battery drill -- The handheld drill worked rather easy (surprisingly)

A machinist friend of mine showed me to put masking tape on the metal where I wanted to make my marks --then use a 1/8" bit just to make dimple in the metal --then drill the holes the size you need --- Slow is better and clamp your work down -- nothing worse than a spinning piece of bar stock

I use plenty of tape over all the terminals I'm not working on -- I had a mishap with my wedding band that taught me well ( millisecond short had my ring glowing and burnt a ring around my finger -- I decided to rotate my connections 90 degrees from your diagram -- therefore your pos and neg terminals are further apart -- this way you have two 3 hole busbars / two 3x3 square busbars / one 6 hole busbar

Fuses add heat (and resistance). You need one fuse per battery. Just size it properly. Putting one between cells will make readings from your BMS off. McMaster Carr carries busbar with reasonable shipping.

Reality is probably that you will be limited by available breaker size and wire size.Am I wrong in thinking that the most the amp flow could be is the max my inverter could draw?

You are going to need bigger wire than 4/0 if you plan to push a constant 900a.

For bus bars there is simply no reason to use smaller than 1/4".

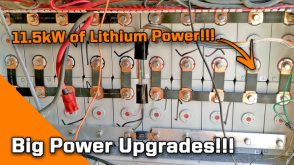

This image shows what the Everlander guy did. He's pretty sharp and typically well thought out designs so would not hesitate to copy this idea. It's also not a theoretical view as he's been all over with this system design. You can see the mega-fuse between bus bars in the bottom. His is a 5P4S design I believe.

BretS

New Member

- Joined

- Mar 30, 2021

- Messages

- 171

I was wondering how it would effect the BMS... no fuse in between packs... Thanks!Fuses add heat (and resistance). You need one fuse per battery. Just size it properly. Putting one between cells will make readings from your BMS off. McMaster Carr carries busbar with reasonable shipping.

A quarter inch by one inch should be able to handle approximately 400 amps with a temperature rise of 30 degrees Celsius. So about 300 amps. The longer busbar should not be a problem, just keep the screw holes as small as possible/reasonable. You might want to consider 3 separate battery packs and BMS to give some redundancy. Even using contactors, you will have problems being able to handle 900 amps.Putting together a 3P4S bank with twelve 310Ah cells and a REC active BMS. I could use some help with Busbars. Will it be ok to buy 1/4" x 1" copper and make my own? Will the longer, 6 terminal lengths be a problem? Thanks in advance!

View attachment 45307

@FilterGuy has a nice resource on fuses. He certainly knows more than I do about the subject.

diysolarforum.com

diysolarforum.com

And Will has a very comprehensive resource as well.

diysolarforum.com

diysolarforum.com

For me, I expect 140 to 150 amps as maximum draw, so I have a 200 amp class T fuse, as well as a 200 amp Bussmann breaker (mainly as an off switch).

Class T fuses are expensive, but regular fuses may not work when confronted with the amps lithium cells can produce.

DC Fuse and breaker Sizing and Placement

To get the paper, click on the orange button at the top of the page The attached presentation gives the fundamentals for picking fuse/breaker sizes and describes where in the circuit they should be placed. You can download the presentation by...

And Will has a very comprehensive resource as well.

Bussman: Selecting Protective Devices

Free PDF teaching how to select and use over current protection devices: Based upon the 2017 NEC® This comprehensive guide to electrical overcurrent protection and electrical design considerations is based on the 2017 NEC®. With over 300 pages...

For me, I expect 140 to 150 amps as maximum draw, so I have a 200 amp class T fuse, as well as a 200 amp Bussmann breaker (mainly as an off switch).

Class T fuses are expensive, but regular fuses may not work when confronted with the amps lithium cells can produce.

Last edited:

You might want to run a straight edge across your terminals --- when you clamp these cells together the terminal heights are not always the same -- if you're using these cells with the m6 shallow threads and thick busbars you'll pull the treads out before they make good contact -- this really isn't much of an issue with a 2 hole busbar -- I was really surprised how much cells terminal heights differed

Since I had that Incident with my wedding ring shorting out -- that Everlander video gave me the heebie jeebies --The way he had all those busbars loose on top of all those cells and placing them every which kind of way in that box -- Tape is cheap -- I cover those Bad Boys (terminals) when ever possible

Good advice on making your own there. The wedding ring is something to watch out for, since there is easily enough amps to totally vaporize your ring. Not just get hot, but literally make it a cloud of rapidly expanding gas (aka explode).I have made Busbars with a drill press and with a handheld battery drill -- The handheld drill worked rather easy (surprisingly)

A machinist friend of mine showed me to put masking tape on the metal where I wanted to make my marks --then use a 1/8" bit just to make dimple in the metal --then drill the holes the size you need --- Slow is better and clamp your work down -- nothing worse than a spinning piece of bar stock

I use plenty of tape over all the terminals I'm not working on -- I had a mishap with my wedding band that taught me well ( millisecond short had my ring glowing and burnt a ring around my finger -- I decided to rotate my connections 90 degrees from your diagram -- therefore your pos and neg terminals are further apart -- this way you have two 3 hole busbars / two 3x3 square busbars / one 6 hole busbar

This image shows what the Everlander guy did. He's pretty sharp and typically well thought out designs so would not hesitate to copy this idea. It's also not a theoretical view as he's been all over with this system design. You can see the mega-fuse between bus bars in the bottom. His is a 5P4S design I believe.

View attachment 45337

Maybe it's just me, but he starts out the video by explaining he blew up his solar controller by not turning it off properly.

I'm not sure I would take his build as "this is what you want". The cells he uses are high quality, but if memory serves me correctly, he has those because he killed his first set (not the CALB). I could be wrong about that.

As someone else noted, he makes me cringe the way he handles busbars and tools.

@chops728 - I still have a crooked finger from a similar incident from many moons ago. I switched to a silicone ring way before they became the cool thing

You didn't say what your max amp load was, but if it's 400 amps or less 1/4" x 1" bars are fine.

Even in a high temp rise of 65°C they are good for a little over 600 amps.

Just as important will be a clean contact area & shrink tubing the bars between cells to prevent accidental shorting.

You didn't say what your max amp load was, but if it's 400 amps or less 1/4" x 1" bars are fine.

Even in a high temp rise of 65°C they are good for a little over 600 amps.

Just as important will be a clean contact area & shrink tubing the bars between cells to prevent accidental shorting.

The serial connection should carry 100% of the current you are using, parallel would only carry "balance" current.Curious, in a parallel/serial battery set-up what carries more current, the parallel or serial connection?

Volts the same, amperage is the same.Curious, in a parallel/serial battery set-up what carries more current, the parallel or serial connection?

Either way, all current is carried across the wires equally.

Similar threads

- Replies

- 2

- Views

- 368

- Replies

- 4

- Views

- 383

- Replies

- 5

- Views

- 438

- Replies

- 4

- Views

- 264