larrylwill

New Member

- Joined

- Aug 22, 2021

- Messages

- 92

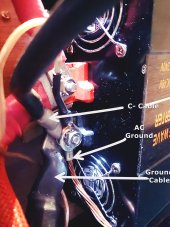

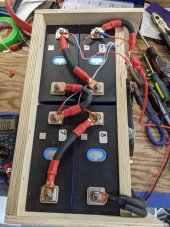

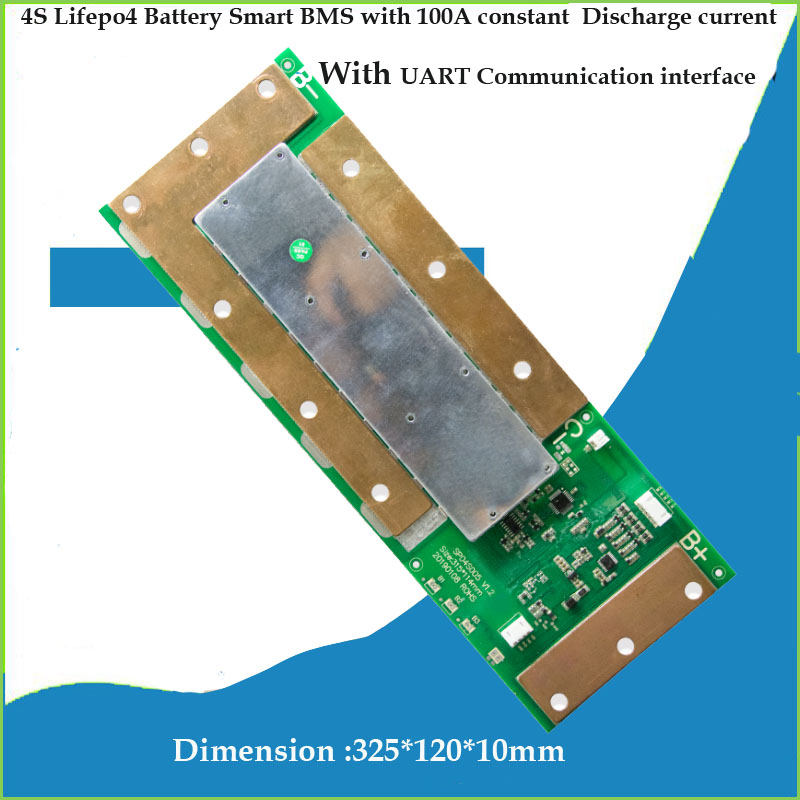

I built a 280Amp LifePo4 pack with Xiaoxiang 150 Amp BMS recently, I added a Inverter, charger, AC switch and installed it in my motorhome. Everything is hooked up correct and working. After a few weeks I found that I have a 0.5amp drain on the battery. Today I was trying to find the phantom load and disconnected the Neg B- battery wire. Only the B+ and C- wires still connected but the 12v system was still active. I found that if I disconnected the Balance wires the battery was no longer connected. So somehow the balance wires are feeding the 12v to the load. Is it possible that one or more of the balance circuits is bad? Right now I only have the B-. C- and balance wires connected. All readings with an ohm meter and the app are correct and everything seems to be working except for this problem. Anything I'm overlooking? I haven't found the 0.5 amp drain yet.

Last edited: