I got pinged, sorta.... I quickly read through the thread (thank goodness it isn't pages long lol) and it looks like you've gotten some good info and number crunching done... I feel the tylenol bottle might have been lightened a bit... I am going to assume you are in North America as you mention both 220/240 but 220 is EU and elsewhere and there's a big difference, 240VAC Split Phase @ 60Hz for USA & Canada.

You haven't mentioned budget, other than the obvious Frugalness that needs to apply nor any mention if you want to stick to products from US vendors only. So I'll leave that laying there.

First off a little clarity on inverters, simple guide is 12V=100W-2500W, 24V=100W-5000W, 48V=100W-10,000W, 72V+=10,000W and up. excluding surge capacities. This keeps the amperage range is a respectable zone providing optimal output, additionally undersized inverters will draw more electricity at a higher rate which will depleted the stored energy faster. This will also increase the DOD and have an effect on the depth for charge/discharge cycles of the cells. For your application requiring 6kw, 48 Volt system is suggested. More importantly, as this is a commercial venture, it is prudent to go with heavier duty equipment to endure the daily & constant demands.

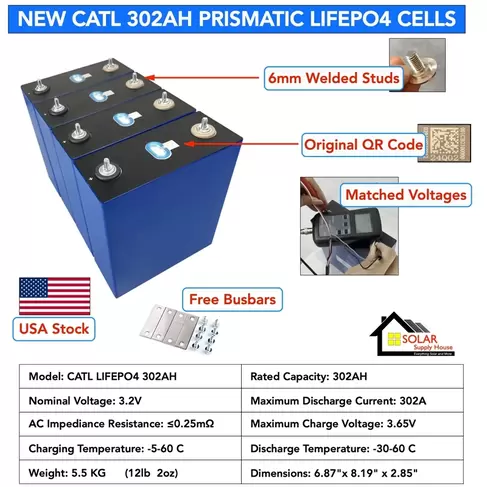

Battery Cells are a bit tricky as well, as you need a healthy sized battery bank but you have limited space and certainly cannot have the batteries under foot or exposed to the on going's within the trailer. There are varied Cost Ratios to Capacity to consider related to cell capacity per dollar and the space used factor as well. As you likely discovered, there are 10AH cells as well as 1000AH cells (don't look at the price) and different cells can handle different out C-Rates as well with the larger cells being more capable of course (but not all, devil is in the details). There are HUGE pricing differences between the various cell brands as you have seen. CALB, Winston, Sinopoly, the "cased" cells are more expensive and are "premium" product lines that are well established with the RV, Marine & Mobile / Industrial users BUT they are no the only Big Players who've been around for decade +. The Aluminium Blue-ee's made by CATL, RJ, EVE ad several companies are just as good but at a lower price point. *There are shyster vendors, but we know of good reputable dealers with good deals too.

You mention up front that you believe you will need 18Kwh per day, allowing for buffer (prevent too deep DOD) and to allow for extra running hours for special events & whatnot... I'll round it to 20Kwh @ 48VDC = 416AH - so KISS applied say 48V/400AH (19.2kwh). You can build one 48V/400AH pack with 16x400Ah cells, or two, 48V/200AH pack with 32x200Ah I certainly would not use cells of a lesser capacity because the space used & complexity.

Insurance Company "may not" accept a DIY Battery Bank, additionally, they can refuse anything that is not UL/CSA etc certified, so Verify with Insurance BEFORE buying anything ! Imagine how happy & joyous you'd be if they told you to rip it all out. THEY DO THAT TOO ! If you want insurance you have to follow their rules.

Inverters, using the AIMS which was offered up previously, for comparison points: NOTE, these are made in China by Sigineer, they are a reasonable VAR (Value Added Reseller) "value" components that will serve their function, They are not very configurable and have their limitations. Their efficiency rating is also "average" in the mid 80% range.

6000 Watt Pure Sine Inverter Charger 48Vdc / 240Vac Input & 120/240Vac Split Phase Output $1951.00 (NOT UL/ETL)

*60A Charger with 240VAC input

** Basic Lithium support.

This 6kw 48 volt AIMS Power low frequency inverter charger is one of the most powerful split-phase inverters available on the market. Great for off-grid & emergency backup power

www.aimscorp.net

8000 Watt Pure Sine Inverter Charger - 48 Vdc / 240Vac Input & 120/240Vac Split Phase Output ETL Listed to UL 1741 $3541.00

no 48v/6kw unit avail. *80A Charger built in, takes 24VAC input

** NO LITHIUM SUPPORT !

This 8kw 48 volt AIMS Power low frequency inverter charger is one of the most powerful split-phase inverters available on the market. Great for off-grid & emergency backup power.

www.aimscorp.net

As this setup will use a 6Kw Inverter I strongly suggest 48VDC system, a Large Inverter capable of taking 240VAC "Shore Power" and charging the batteries is a reasonable possibility, provided the charger has enough amperage relative to the battery packs. Also a consideration, if this will be recharged with Grid Power the likelyhood is that the majority of the charging will occur during Off-Peak hours when the cost per Kw from the grid is lowest, therefore a slightly longer charge time may be ok, if the system is fully recharged by the morning when you have to get going.

IF you require a separate Charger System there are different ways to configure the battery bank & the BMS' to support it. If using an Inverter Only and a separate charging system, then a "Separate Port BMS" configuration is likely most appropriate, if using an combined Inverter/Charger then a "Single Port BMS" configuration will work best. ! NB ! FET Based BMS' have serious limitations to large amperage handling and must be carefully considered. BMS Choices depend on the Battery Bank and the sizing & loading of the Inverter and how you intend to charge the battery bank.

Hope that helps, sorry it's a long read.

Sheesh and all this and I just got to the bottom of Mugga #1 oivey, refill time. (excuse the typonese eh!)

Steve

PS: Buck Converters are the lowest of the low cheapo answer and fail a lot... a proper step down converter will be required as this is commercial use and will have to be completely reliable, dependable & safe. I've melted down buck converters, it's too easy to do and when they fail it can be nasty. They seem to fail and allow full voltage through... imagine 12V device getting 48V or 59V (which charging) instant magic smoke.