Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

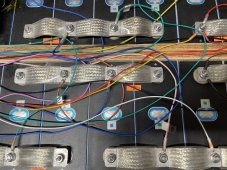

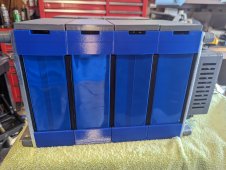

I have a couple hundred pounds of 280ah CATL cells on the way.. I’ve read a lot on here about this.. Seen Wills videos and his sideways cell configuration with solid busbars. Seen Offgridgarages videos and his are not sideways but he leaves space between each cell for expansion and uses solid busbars.. both options seem like good ideas.. Also realize that a lot of premade batteries have the busbars welded to the cells and just straps around the cells with spacers.. Wills way imo isn’t clean looking due to the cells not being put together wide side to wide side so I would prefer Offgridgarages method but is the amount of space between his cells enough for expansion to not cause the busbar nuts to loosen over time? I am getting CATL cells (all that’s available atm) and from what I have read they are more prone to expansion than EVE cells so that makes me wonder if compression is more important than it is with EVEs.. Will the CATLs need more room to expand than what Offgridgarage has between his EVE cells.. If the CATL cells do expand more then should I want to stop that expansion, should I worry about that expansion more than if I was getting EVE cells and therefore compress the CATLs. And since they might expand more, instead use flexible busbars of some sort due to the extra expansion.. wish there was a definitive list some where that tells us exactly what to do with each type of cell for solar storage.. I understand compression isn’t needed due to the whole calendar life will come before any kind of degradation to worry about due to cycles. But does that theory change due to damage to the cells from expansion and more so with CATLs that could expand more so than EVEs due to CATLs thinner wall construction.. Open to any advice, opinions or thoughts..