Completed a build of two 48v packs made up with 105ah EVE cells. The battery busbars that came with the batteries are 12mm wide by 2mm thick copper. According to the calculator in the link below, the copper bus bars that came with the batteries can only carry just over 28amps. Means this 48v pack is limited to 1.3kw. Is this accurate? I've pulled more than 1.3kw out of each pack and didn't notice any heating but wasn't for a long duration. Feel like I'm missing a component in the math here or maybe this calculator is wrong.

Link to busbar ampacity calc: https://www.allumiax.com/bus-bar-size-calculator

Edit:

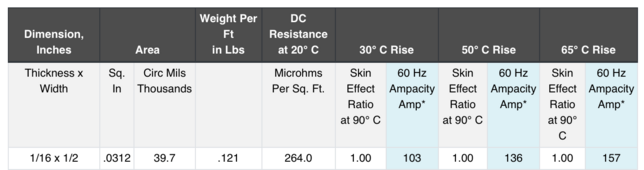

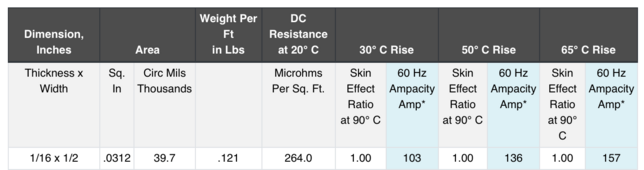

This calculator shows that 2mm thick x 12mm wide (1/16" by ~1/2") can do 100 amps.

Link: https://stormpowercomponents.com/te...es/copper-alloy-c11000-busbar-ampacity-chart/

Very confused.

Link to busbar ampacity calc: https://www.allumiax.com/bus-bar-size-calculator

Edit:

This calculator shows that 2mm thick x 12mm wide (1/16" by ~1/2") can do 100 amps.

Link: https://stormpowercomponents.com/te...es/copper-alloy-c11000-busbar-ampacity-chart/

Very confused.

Last edited: