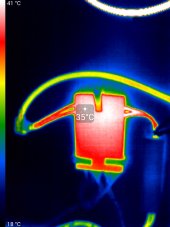

So i'm all up & running & want to do some thermals to see how its all going.

2x5kw Deye hybrids, 2x16kw 48v packs with JK BMS

Big DC Cabling is 35mm welding cable, some smaller stuff which is being upgraded.

Discharged at 8kw for an hour & did some thermals... EEPERS

BMS happy at 35-38c, inverters arent that hot (66/48 c), cabling all ok...

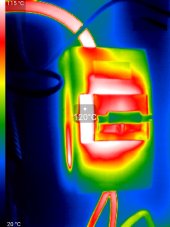

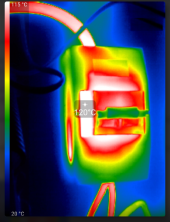

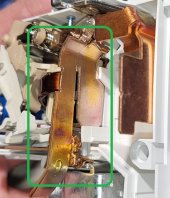

TOMZN 125A Circuit breakers are WAAAAY TOO HOT, no way i'm keeping them in place. Was running 85-90A through them & they were 120c!!!

This is a fire waiting to happen.

I've got Class T's on the batteries, the breakers are just used to isolate inverters as i need - never used to switch anything, but no way i'd use them in an emergency!

2x5kw Deye hybrids, 2x16kw 48v packs with JK BMS

Big DC Cabling is 35mm welding cable, some smaller stuff which is being upgraded.

Discharged at 8kw for an hour & did some thermals... EEPERS

BMS happy at 35-38c, inverters arent that hot (66/48 c), cabling all ok...

TOMZN 125A Circuit breakers are WAAAAY TOO HOT, no way i'm keeping them in place. Was running 85-90A through them & they were 120c!!!

This is a fire waiting to happen.

I've got Class T's on the batteries, the breakers are just used to isolate inverters as i need - never used to switch anything, but no way i'd use them in an emergency!