I can't see that you've ever fully charged these batteries. If that's the case, then they are almost certainly grossly out of balance resulting in vastly diminished capacity. You may literally have both full and empty cells in the pack. If so, they may exhibit erratic behavior during charging and discharging or just sitting there for that matter.

In retrospect, because we're 3 pages in, and there hasn't been any movement on your part, if the batteries are under warranty, I recommend you contact them for warranty replacement. If they are truly as out of balance as I indicate above, it may takes weeks/months to get them sorted.

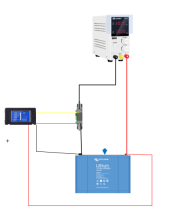

Until you have the means of reliably charging the battery to a known full state, or at least can characterize the behavior, you can't do any diagnosis. I know you want a black and white answer, but it's a process. The first step is a controlled charge. This first step may be all that's needed to diagnose, i.e., if the batteries refuse to take a charge under controlled conditions, they are bad. If they do take a charge, you need to test their capacity in some way. This requires a means of measuring their output. You don't have that either as far as I can tell.

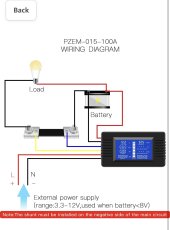

@Consumerbot3418 recommended a $21 tool that will allow you to monitor both charging and discharging and measure capacity.

Hopefully, you can be convinced to take action before we get to page 4.