Bozzydogg02

New Member

Hi all,

My knowledge on this stuff is very limited, I don’t understand how to do the equations to calculate exactly what I need so I thought if I just overestimate everything I should be fine for a long time.

Wrong.

Where there is now just the one battery powering my LED light and a 5v USB port there were 5 more ‘solarflex’ 110ah which have all died.

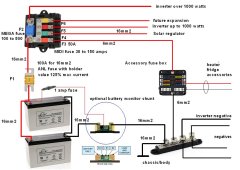

The solar panels are 100w each and there is 5 of them in series.

I have a 400w wind turbine to add to it for additional charging.

I would also like to add another USB port, cool box/fridge and a diesel heater to the fuse board.

We used (it is currently disconnected) the inverter for charging laptops (60w charger for 3 hours max) charging our little vacuum cleaner (this takes 4 hours to charge but is charged maybe once or twice a week) and to charge my drill here and there if required. Also run a small 60w projector and desk fan off it in the summer.

What kind and how many batteries suit this exact system?

Please excuse the dust in the photos we’ve not been able to charge our hoover ?

Also if anyone can spot an error with how I’ve connected anything, please point it out I wont take offence I’m not a spark just a diy’er seeking help from the experts.

Thanks!

My knowledge on this stuff is very limited, I don’t understand how to do the equations to calculate exactly what I need so I thought if I just overestimate everything I should be fine for a long time.

Wrong.

Where there is now just the one battery powering my LED light and a 5v USB port there were 5 more ‘solarflex’ 110ah which have all died.

The solar panels are 100w each and there is 5 of them in series.

I have a 400w wind turbine to add to it for additional charging.

I would also like to add another USB port, cool box/fridge and a diesel heater to the fuse board.

We used (it is currently disconnected) the inverter for charging laptops (60w charger for 3 hours max) charging our little vacuum cleaner (this takes 4 hours to charge but is charged maybe once or twice a week) and to charge my drill here and there if required. Also run a small 60w projector and desk fan off it in the summer.

What kind and how many batteries suit this exact system?

Please excuse the dust in the photos we’ve not been able to charge our hoover ?

Also if anyone can spot an error with how I’ve connected anything, please point it out I wont take offence I’m not a spark just a diy’er seeking help from the experts.

Thanks!