Horsefly

Solar Wizard

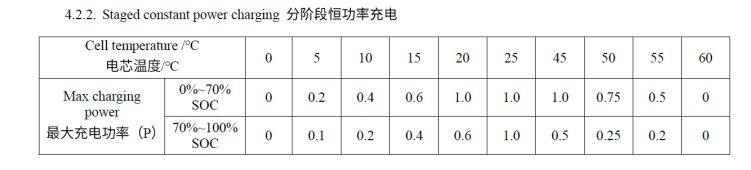

That's still 175W at 12V, which seems like lots to me. I was doing 24W for twice as many cells.Alternatively, could i use 24V pad (30*30cm, 350W), but supply it with 12V power? This should halve the heat production right?

There really isn't any reason to try and heat things up quickly. You are just trying to maintain a temperature somewhat above freezing. If you use a lower number of watts, the heater may be on more of each 24h, also consumes less power and keeps the temp where you want.