ruralsolar

New Member

Yes.Keep in mind the tax credit is non-refundable, which means if your actual tax liability is less than the credit, the difference is carried forward and its value falls with inflation until it is used up in future years.

Yup.Tax credit not refund.

I did create a sheet and exaggerated some material costs so I know a "no more than" cost barring any crazy increases of materials. Ground mount is a Sinclair set up, so just under 6k for that not including shipping which is bundled for everything from the seller (panels, mount, inverter, materials).I doubt that would mean it is your costs, for example, your looking at about 10K for having a ground mount array ( vs roof mounted ) based on your number of panels and the msrp of the racking you mentioned the manufacture. ( Add in concrete and other materials to dig, mix, pour, brace and shipping )

Then there is distance, further away, costs go up fast, you need trenching, conduit, wire which is expensive.

My point is not that I am suggesting you are wrong, it's that you do not have your own spreadsheet of costs for your proposed system, so you really don't know. In any solar system, it starts with full plans and bill of materials and labor and quotes on all parts, as every installation is unique.

Getting the money and permits are the last step in the process, from what you have wrote you need a costed BOM.

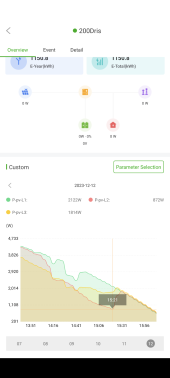

Hmmmm ok interesting. Will have to look.No quite. 19kW DC PV can be changed connected, but there is a max of 15kW delivered to battery and ac. Anything above that is wasted. There are also threads talking about problems getting over 13kW with DC solar. If panels are oriented so that max 13kW at any one time, then that is fine. Otherwise, I recommend anything over 13kW be ac connected PV.

The increase in production being in the northeast is more important to me right now over battery backup tho they'll be next on my list "to do"Personally I would ditch the adjustable tilt for the panels and put that towards a battery, you will love it when the solark switches over the battery during a power outage. You will feel like a king in the hood LOL